Storing Construction Supplies in the Philippines: Common Mistakes to Avoid

What are the common mistakes to avoid when storing construction supplies in the Philippines?

- Ignoring proper sheltering

- Stacking materials improperly

- Inadequate security measures

- Neglecting regular inspections

- Overlooking safety precautions

Overview

- In this article, we explore the most common mistakes businesses make when storing construction supplies, with a focus on steel materials.

- These mistakes, such as ignoring proper sheltering, improper stacking, inadequate security measures, neglecting regular inspections, and overlooking safety precautions, can lead to significant issues, including rust, theft, accidents, and increased costs.

Storing construction supplies properly is critical to the success of any construction project, especially in the Philippines, where the tropical climate and unique challenges can affect the quality and integrity of materials. From steel beams to equipment, proper storage is essential to protect these valuable assets from damage and prevent unnecessary costs. However, many businesses overlook key storage practices, leading to issues, such as rust, theft, and accidents that can delay projects and inflate budgets.

In this article, we will explore some of the most common mistakes to avoid when storing your construction supplies in the Philippines, helping you ensure your materials remain in top condition, your team stays safe, and your projects run smoothly.

Ignoring Proper Sheltering

Construction materials like steel exposed to prolonged direct sunlight or rain are at a high risk of rapid deterioration. Prolonged exposure to the sun causes the metal to heat up, which can lead to thermal expansion and stress, weakening its structural integrity over time.

Rainwater, on the other hand, can cause rust and corrosion to form on steel surfaces, compromising its quality. These environmental factors can happen when you don’t have the right shelter for your materials. This reduces the lifespan of the materials but also increases costs, as the need for replacements and repairs escalates.

To avoid these issues, it’s essential to store steel materials under proper shelter, such as warehouses or sheds that protect them from direct sunlight and rain. Using covered storage areas helps maintain the supply’s integrity by preventing rusting and deformation caused by the elements.

Ensure as well that these shelters are well-ventilated to allow air circulation, which helps reduce moisture buildup that can further accelerate corrosion.

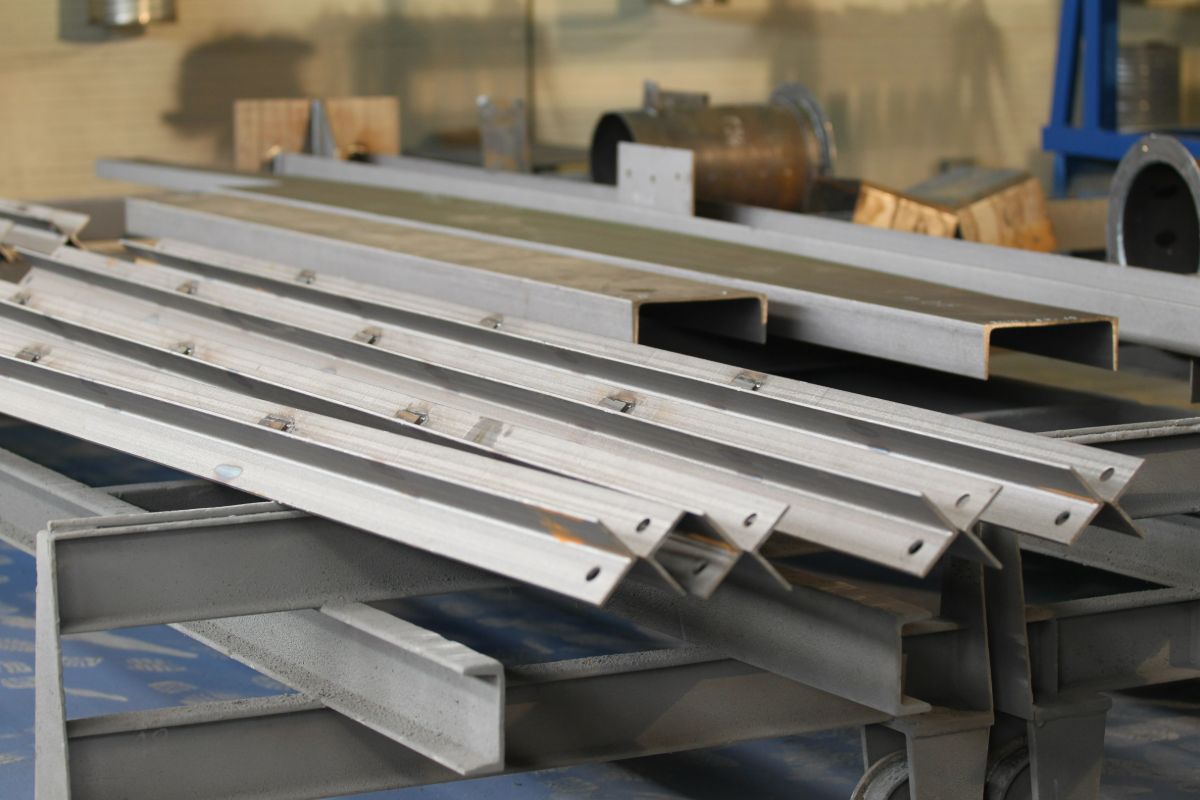

Stacking Materials Improperly

When your supplies are piled unevenly or on unstable surfaces, it’s not just the material that’s at risk, your entire operation could be affected. Uneven stacking can lead to deformation, making it unusable for precise applications like structural reinforcements or customized fittings.

Imagine trying to use warped steel for a high-stakes project, it’s a costly setback that could have been avoided with proper storage practices. Worse, unstable stacks increase the risk of accidents, which can delay projects and harm your team, leading to unnecessary downtime and liability concerns.

Invest in proper racking systems or use flat, secure surfaces to stack your steel safely. Organized storage protects your materials and ensures your workplace is safer and more efficient. A well-structured storage system will also make it easier to locate specific items and reduce the risk of damage during handling.

Inadequate Security Measures

In 2023, theft recorded the highest number of criminal cases against properties in the Philippines, with around 12,700 reported incidents. For construction businesses, steel materials and other high-value supplies are prime targets because they are easy to resell and difficult to trace.

Without proper security, a single incident of theft can result in significant financial losses and project delays. Beyond the monetary impact, the loss of essential materials can harm your company’s reputation, especially if it causes missed deadlines or incomplete projects.

Consider securing your storage area with perimeter fencing, surveillance cameras, and proper lighting to deter potential thieves. You can also employ on-site security personnel and limit access to authorized personnel only to further safeguard your materials.

Keep a detailed inventory of stored supplies to quickly identify missing items and prevent unauthorized movement.

Neglecting Regular Inspections

Steel materials are especially vulnerable to rust and damage due to the country’s humid and tropical climate. If early signs of rust go unnoticed, the problem can quickly escalate, weakening the steel and making it unsuitable for use in critical projects. The longer damaged materials sit in storage, the greater the risk of widespread corrosion, which can compromise the integrity of your supplies and lead to unexpected costs for replacements.

The solution is simple yet effective: schedule routine inspections of your stored materials. Check for any signs of rust, warping, or other damage, and take immediate action to address the issue.

Overlooking Safety Precautions

Improperly stored materials, such as steel beams or heavy equipment, pose risks like falling objects, collapsing stacks, or slips and trips in the storage area. These accidents can result in injuries to workers, damaged materials, and delays in project timelines.

For example, unstable steel stacks could topple over, causing severe harm to employees and even fatal accidents in extreme cases. In addition to the human cost, such incidents can disrupt operations and lead to financial losses, legal liabilities, and damaged reputations.

Consider implementing measures such as secure stacking, clear labeling of materials, and proper aisle spacing to reduce the chances of accidents. Ensure that workers handling the materials are trained in safety protocols, including the use of personal protective equipment (PPE) and safe handling techniques.

Key Takeaway

Proper storing of construction supplies in the Philippines is essential to ensuring the quality, safety, and longevity of your materials while minimizing risks and costs. These proactive steps not only safeguard your assets but also build trust with clients by ensuring projects stay on schedule and meet quality standards.

Ready to elevate the strength and durability of your construction projects? At Metal Exponents Inc., we provide premium steel materials designed to withstand the toughest conditions. Don’t let poor storage or quality materials hold your projects back. Contact us today for reliable, high-quality steel solutions that keep your operations running smoothly.