Choosing Between Ductile Iron or Steel Pipes

What is the difference between ductile iron and steel pipes?

- Carbon Content

- Function and Construction Process

- Tensile and Yield Strength

- Abrasion Resistance

- Corrosion Resistance

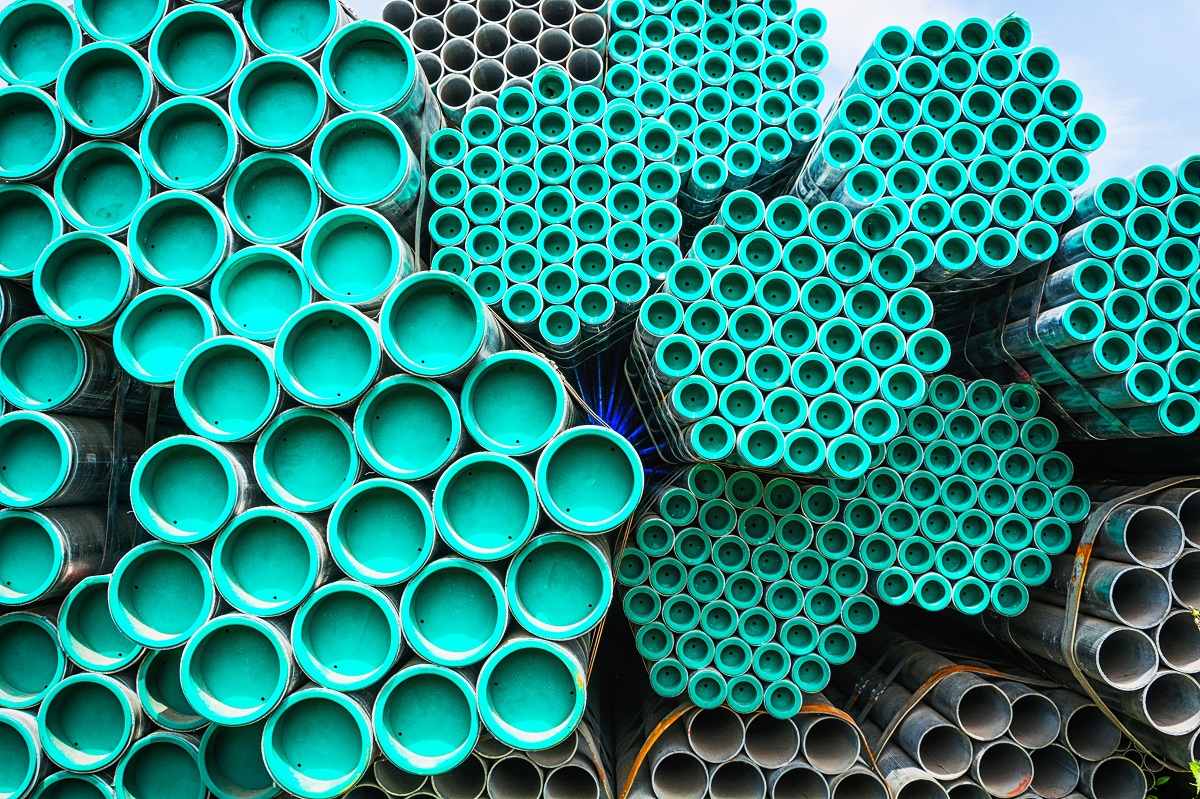

When it comes to pipes, ductile iron and steel pipes look quite similar at first glance. They may appear to be identical because both are metal alloys, however, there is a distinct and complete difference between iron vs steel pipes. Although, if you were to ask one is better, the answer lies upon your project and their deciding factors. And today, we’ll be covering all the aspects of ductile iron and steel pipes to help you make an informed decision. Let’s take a deeper delve into both of their qualities when it comes to engineering, installation, operations, and cost. Continue reading to learn more!

Carbon Content

The main difference between ductile iron and steel pipes are its carbon content. While ductile iron has a carbon content of 3.0%-3.9%, steel normally holds a carbon content of 0.8-0.60%. With carbon content, you get to discover the pipe’s hardness, strength, and hardenability.

Function and Construction Process

Another significant between ductile iron pipes and steel pipes is its manufacturing process and construction methods. Ductile iron pipes are manufactured with seams that allow for connection to other pieces of pipes with the help of connector valves. It is also made with larger inside diameters than steel pipe. On the other hand, steel pipes, are needed to be welded to be used for an application. Ductile iron is stiffer and has thicker walls compared to steel pipes.

When it comes to function, steel pipes are usually used in objects such as fences, oil lines, bridges, and water facilities. As for ductile iron, it was originally built for use in gas industry applications. But it also holds an excellent strength and durable profile that allows it to be used effectively in a wide array of industrial applications, automotive parts, wheels, gears, pump houses, machine frames, and much more.

Tensile and Yield Strength

With regard to tensile strength, there is no extreme difference between ductile iron and steel pipes. Both seem to have strong yield strength. Though ductile iron holds a fairly greater yield strength of 40ksi, while cast steel can only reach a yield strength of 36ksi.

Abrasion Resistance

Because of its high volume percentage of graphite, ductile iron has much higher abrasion than cast steel. This is why it is usually utilized in friction wear mechanisms such as engine crankshafts.

Corrosion Resistance

Both of these pipes are said to be corrosion resistant. If one were to ask which pipe is more resistant to corrosion, it can be difficult to generalize as there are a number of factors that can trigger and influence corrosion. They also hold different corrosion mechanisms. For ductile iron pipes, its uniform surface oxidation forms an oxide layer on the external surface. On the other hand, with steel pipes, its corrosion mechanism works by its pitting, in which the loose scale of iron oxide will sulfate and forms on the external surface.

Key Takeaway

Pipes such as ductile iron and steel pipes may be mistaken for one another because of their visual similarities. Although these are both metal alloys, there are many factors and elements that set them completely apart from each other. When it comes to choosing between ductile iron and steel pipes, the best option will always depend on your project’s preference and type of application.

Looking for steel pipes and ductile iron pipes? We source from the world’s best exporters here at Metal Exponents. We’ve been in the industry for more than 40 years, and we are also one of the largest steel importers in the Philippines. Click here to contact us today!