Cost-effective Construction: Balancing Steel Bar Size with Project Budget

Overview

- This article explores the critical aspects of balancing steel bar size with project budgets in construction.

- It highlights the role of steel bars in reinforcing concrete structures, discusses strategies for cost-effective sizing, and addresses factors such as structural loads, seismic activity, and spacing requirements.

- By consulting structural engineers, embracing standardization, and minimizing waste through meticulous planning, construction projects can achieve a balance between structural integrity and budget constraints.

Balancing steel bar size with the project budget is crucial for cost-effective construction. The choice of steel bar dimensions impacts the structural integrity and the overall cost of a project.

This article delves into the considerations necessary for selecting the appropriate steel bar sizes in the Philippines, aligning them with budget constraints while ensuring safety and compliance with standards. Read on to learn more.

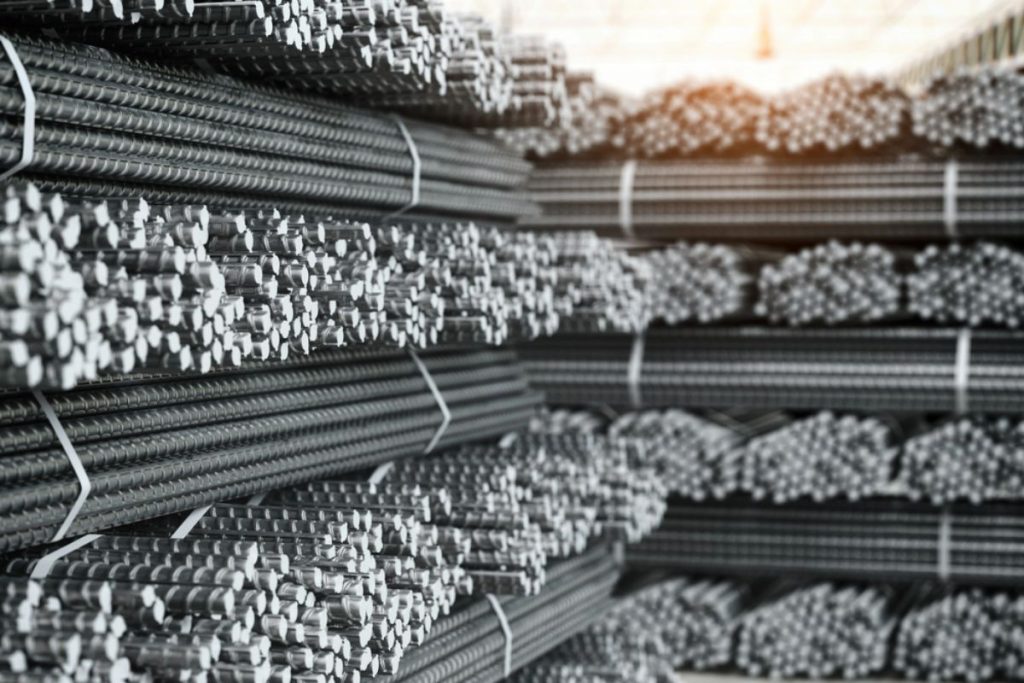

The Importance of Steel Bars

Steel bars, also known as rebar, are essential in reinforcing concrete structures. They can absorb tensile and shear stresses that concrete alone cannot withstand. This makes them indispensable in the construction of foundations, beams, and columns, ensuring stability and strength.

Their ridges improve bonding with concrete, preventing slippage and increasing structural integrity. Moreover, using appropriately sized and graded steel bars enhances the resilience of the building against seismic activity and heavy loads, ensuring compliance with safety standards and extending the lifespan of construction projects.

How to Balance Steel Bar Size with Your Project Budget?

Balancing steel bar size with your project budget requires a strategic approach that involves consulting with structural engineers, embracing standardization, and minimizing waste through meticulous planning.

Consult a Structural Engineer

These professionals determine the optimal size and grade of steel bars required for various structural elements, ensuring safety and cost-effectiveness. They can calculate load requirements and stress points, as well as recommend the most efficient use of steel. This prevents costly over-specifications and ensures compliance with building codes and regulations.

Embrace Standardization

You can take advantage of bulk purchasing and minimize expenses when you use standard sizes and grades of steel bars. They also streamline the construction process, reducing labor costs and minimizing errors during installation. This enhances efficiency and ensures your project aligns with industry norms, facilitating easier procurement and faster project completion.

Minimize Waste through Planning

Detailed project planning involves precise measurements and calculations to ensure that steel bars are cut and used efficiently, reducing off-cuts and scrap. Implementing strategies such as just-in-time delivery can also help in managing inventory and reducing storage costs. By coordinating with suppliers and contractors, you can schedule deliveries in line with construction phases, further minimizing waste and ensuring that materials are used judiciously.

Factors Affecting Steel Bar Size Selection

Selecting the appropriate steel bar size is crucial for ensuring structural integrity and cost efficiency in construction. These considerations help achieve a balance between safety, performance, and budget constraints.

Analyze the Structural Loads

Structural loads include dead loads (permanent static loads such as the weight of the structure itself), live loads (temporary dynamic loads such as occupants and furniture), and environmental loads (wind and other natural forces). Each affects how the structure bears weight and withstands pressure.

For instance, dead loads are permanent, static forces exerted by the weight of the building itself, including walls, floors, and roofs. Accurate assessment ensures the steel bars can support the constant, unchanging weight without excessive stress or deformation.

Consider Seismic Activity

Earthquake-resistant construction requires steel bars that can withstand the forces generated during seismic events. The bars must offer high ductility, allowing them to bend and absorb energy without breaking. Engineers often use higher-grade steel and larger bar sizes to enhance the structure’s flexibility and resilience, ensuring it can endure the stresses and strains caused by ground movements.

Adhere to Spacing Requirements

Proper spacing ensures these bars work together to distribute loads evenly and prevent structural failures. If bars are spaced too far apart, the concrete might not bond effectively, leading to potential cracks and weaknesses.

Conversely, overly close spacing can lead to material wastage and increased costs. Building codes and design standards specify optimal spacing based on the type of structure, load conditions, and bar size, helping to achieve a balance between safety and budget.

Key Takeaway

Balancing steel bar sizes in the Philippines with your project budget requires thorough planning. Considering the factors outlined in this article can help you achieve a balance between structural integrity and cost-effectiveness.

Building a reliable textile operation requires strong foundations. At Metal Exponents Inc., as a reliable imported steel supplier in the Philippines, we understand the specific needs of different projects. We offer a wide selection of high-quality steel bars sourced from trusted partners worldwide. Contact us today to discuss your project requirements and discover how we can help you achieve optimal steel bar selection.