How to Check Sheet Metal Quality

How to check sheet metal quality?

- Cupping Test

- Coordinate-measuring machine

- 2D Inspection/3D Scanning

- Quality Audit

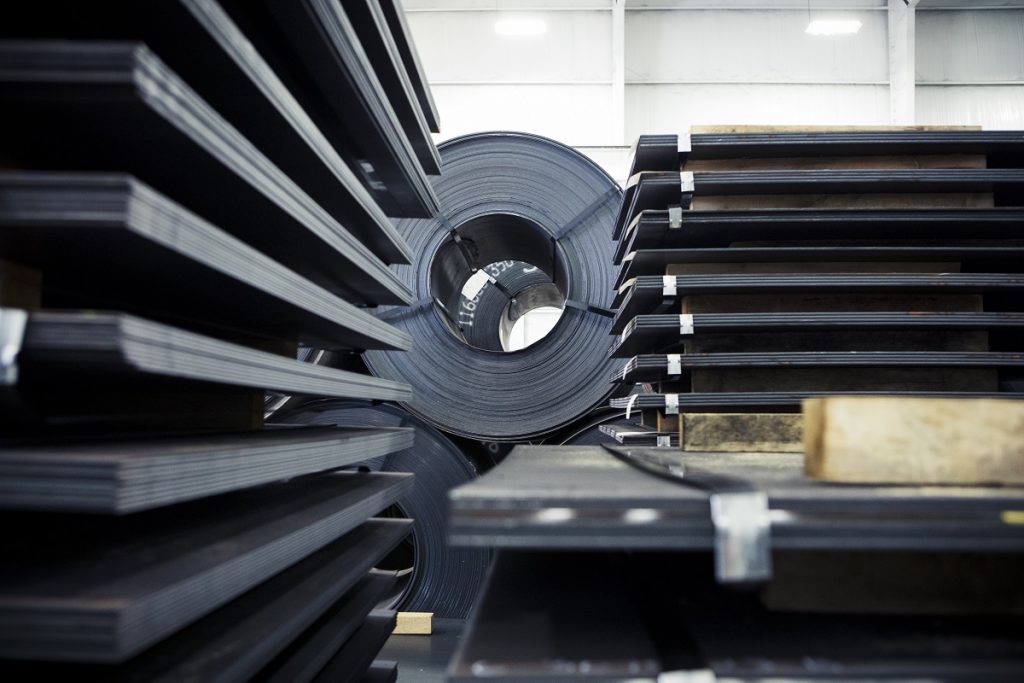

Being in the metalworking industry also means you’ll be handling sheet metal at some point in your career. It is a very common metal product that has plenty of applications, and fabrication usually happens within the factory. Sheet metal is a relatively thin material, which means compared to other products, it can be more prone to damages and imperfections. But any good metalworker should know how to check sheet metal quality.

If you’re not yet familiar with it, we don’t blame you. Not everyone has the necessary expertise and machinery to do this. Checking the quality of sheet metal requires special tools for you to use. Here, we’ll talk about the different tools and methods you can use for checking sheet metal quality. If you want to learn more, keep reading below!

Cupping Test

The first method we’ll talk about is the cupping test. This method is great, but you would still need workers in the field to ensure the quality of the sheet metal they’re receiving. Obviously, you would need a cupping machine to do this. The cupping test machine tests the overall strength and ductility of the sheet and even the quality of paint in the metallic substrates. With this method, you’d be able to learn how well the sheets will do under harsh weather and other unforgiving situations.

The test itself is simple. You put the sheet metal against the cup in the machine. When you turn it on, the machine applies a specific amount of force and creates a cup in the sheet, hopefully until making a crack and letting the light pass through. Once that’s done, the workers should inspect the cup created and measure the depth. It will then be calculated with the amount of force applied to the sheet to see how well it did in resisting the force. This will give you a good idea of how much the sheet metal will be able to resist, and how well it will do in harsh climatic conditions.

Coordinate-measuring machine

The coordinate-measuring machine or CMM is another simple machine that uses specialized robotic arms to measure the dimensions of an object. This machine has been used to check sheet metal quality before, but it is not as effective and efficient as the other options in this list.

To give precise measurements, the arms must be calibrated perfectly. A machine like this would not work well on the factory floor as all the activity going on will make it prone to bumps. A single wrong movement can easily mess up the calibration and make the measurements inaccurate.

They are also slow and costly to use. You would need a skilled operator manning the CMM to make measurements, and the measuring process itself is tedious, sometimes needing to do it multiple times for accuracy’s sake. A mechanical process like this just wouldn’t be too good for checking sheet metal quality.

2D Inspection/3D Scanning

Advancements in technology have given us the ability to scan sheet metal in 2 dimensions within only a few seconds. With a good quality 2D inspection system, a single click can set it off to automatically make the necessary measurements on a piece of sheet metal. You only need to place it on the machine, on a backlit table and it will do the rest. Even punched and non-flat sheet metals can be measured with this machine, and it’s also great for reverse engineering structures.

The reason for this is that after scanning, it gives you the result in a CAD file. Unlike the CMM, where everything is manual up to the mechanical arms, this method is mostly non-contact and automated. Moreover, it has no moving parts and you don’t need an employee manning it all the time or recalibrating it every now and again. With the CAD files, you can create a quick inspection report even with tolerances. And it will all happen within 15 seconds.

All of these features ensure that 2D inspection is faster and more efficient than CMMs.

Quality Audit

Testing the quality of sheet metal also means checking up on it over time. Good QA workers would maintain a regular quality audit of the sheet metals. This is a more long-term approach to learn more about the metals you are using, and it is necessary especially when you have a new supplier. Just perform a QA inspection regularly and pay attention to the results.

Key Takeaway

Knowing how to check sheet metal quality is yet another way to make everyone’s job easier and widen your horizons in the industry of metalworking. These methods are good methods for as long as you do them correctly and in the right context.

One of the best ways to ensure sheet metal quality is by getting them from a trustworthy and reputable source. Metal Exponents has been at the top when it comes to supplying the finest metal products you can find in the continent, including sheet metal. Take a look at our products here, and feel free to contact us if you’re interested!