5 Most Common Metal Alloys and Their Uses

What are the most common metal alloys?

- Brass

- Carbon Steel

- Stainless Steel

- Bronze

- Aluminum Alloy

In the metal industry, there are many different types that could be used, and part of the job is knowing what each metal is best used for. Experienced metalworkers should already be knowledgeable about the uses of the different types of metals. They also know that most metals used in the industry are metal alloys. The most common metal alloys are even mistaken as pure metals sometimes.

Metal alloys are combinations of two or more different elements that make up a new material. This can be a pairing of two metallic elements or one metal and one non-metal. To learn more about these alloys, keep reading!

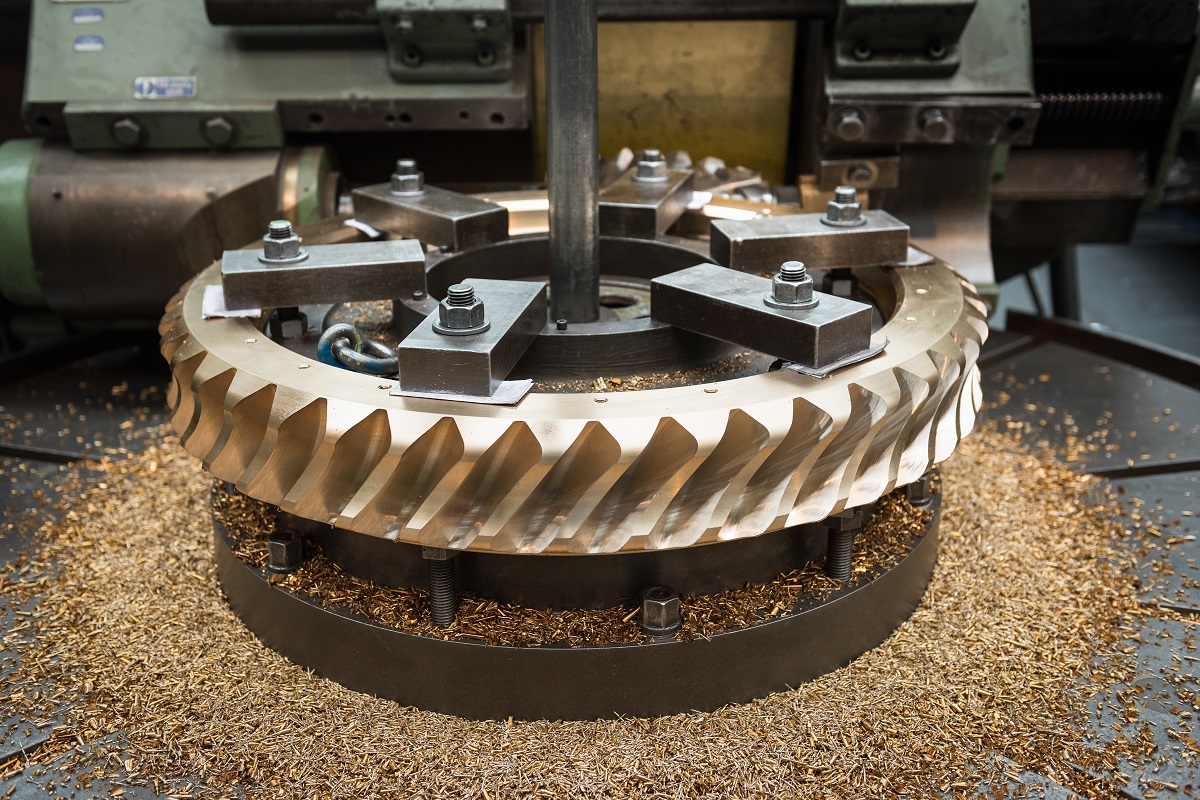

Brass

Brass is the combination of copper and zinc that is one of the most common metallic non-ferrous alloys that you’ll see in your everyday life. It’s known to be tarnish resistant and low friction, and it’s a relatively soft metal. Its malleability makes it easy to machine, and that, in turn, makes it a good metal for equipment parts. Some variations of brass may include iron, lead, aluminum, manganese, or silicon.

You’ll typically see brass as valves, gears, braces, bearings, and base plates. It is also famously used for locks and musical instruments. In fact, there’s a whole family of instruments that are all made of brass, including trumpets, saxophones, trombones, and French horns.

Carbon Steel

The main components of carbon steel, as you can expect, are iron and carbon. But you would also find trace amounts of other metallic elements in them. Copper, manganese, and silicon are known to be included in small percentages in carbon steel. Although it has relatively low corrosion resistance, it is still the most used metal in the world. Over 85% of the world’s steel production is carbon steel.

You can find this alloy almost everywhere, and a big factor is its low cost. Additionally, it also has high pressure and high strength requirements. Its ubiquity is also reflected in its versatility, as the alloy can be mixed with other metals to add some extra properties. For example, adding chromium to carbon steel would increase both its strength and wear resistance. You can combine carbon steel with many metals such as cobalt, nickel, tungsten, and vanadium among others.

Stainless Steel

Stainless steel is another metallic alloy that you encounter quite often in your daily life. It is mostly made of iron with added levels of chromium, carbon, nickel, or molybdenum. The added metals only take up over 15-30% of the whole material. Stainless steel is a metal that doesn’t rust, thanks to chromium. When it interacts with oxygen, a chromium oxide layer is formed on the surface instead of rusting. That’s why it’s used for kitchen materials, medical equipment, and some hardware and machinery.

Bronze

Unlike the other alloys discussed, bronze is made mostly out of copper instead of iron. This combination of copper and tin is one of the earliest metals known to man. Other than its historical significance, bronze still finds many uses in today’s society. The alloy is highly ductile, has low friction, and does not produce a spark when struck. Its color comes from the patina formed when exposed to oxygen.

Bronze can be combined with other metals to expand its versatility. It can be used for musical instruments, electrical connections, and ship propellers. Most people don’t know this, but the “copper” coins we have are actually bronze. And of course, bronze is a famous material for sculptures.

Aluminum Alloy

Aluminum by itself is already a very useful metal, but it isn’t durable enough for more demanding applications. That’s why aluminum alloys are created — to take advantage of the properties of both metals. Aluminum alloys are some of the most widely used non-ferrous metals in the metal and construction industry. You will find aluminum mixed with manganese or copper to give the metal more strength and hardness.

These alloys are most commonly used for power management. Its benefits are fully reaped in electronic technology like electric module packaging. Other uses include being part of the automotive body structure and wind and solar power generation.

Key Takeaway

After reading about the most common metal alloys, you’re one step closer to being an expert in metalwork. Not only that, knowing about these metal alloys and their applications is a big plus even when your expertise is something else. More knowledge of building materials, or what your equipment is made of, will always be an advantage, especially in times of crisis.

No matter the metal alloy you would like to use, its usefulness will still depend on the quality of the material. Good quality metal is more attainable than you might expect, especially because you’re already in the right place! Metal Exponents is the leading supplier of metal products in the Philippines, with products coming from countries all over Asia. Feel free to browse through our products here, and contact us if you’re interested!