Steel vs Aluminum: The Key Differences

What are the key differences between steel vs aluminum?

- Strength

- Weight

- Corrosion Resistance

- Cost

- Applications

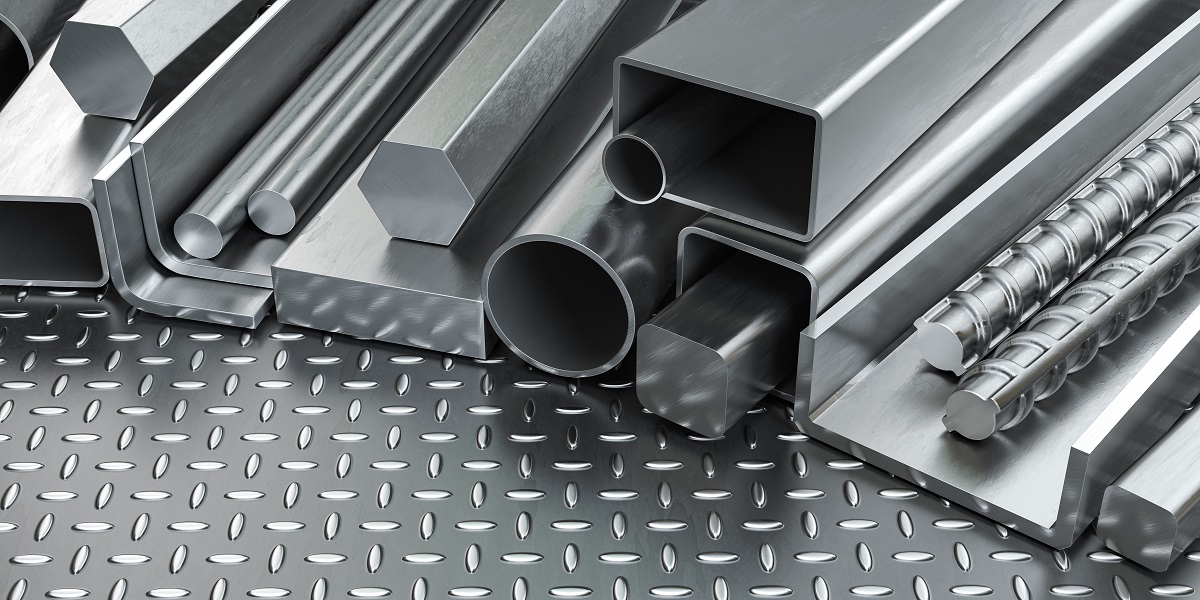

Steel and aluminum are two of the most popular materials for all kinds of parts and structures in the world. In the everyday life of a regular person, it’s not difficult to see how much we rely on both of these metals. Despite their practically ubiquitous presence, their similar appearances make them difficult to distinguish at times. But there are actually several key differences between steel vs aluminum.

Each metal has its own niche in the wide variety of industries where it can be applied. Their physical and chemical characteristics can cater to the specific needs of some industries, so they are both useful in their own way. To have a better understanding of the difference between steel and aluminum, keep reading!

Strength

Most of the time, metals are used for their strength as opposed to older structural materials like wood. In this regard, steel is known to be one of the most durable building materials there are. Steel can be relied upon if you need a material that won’t easily bend or break, and can withstand the challenges of weather, temperature, and even physical pressure.

Aluminum, on the other hand, is better known for its malleability than strength. It is more susceptible to dents and holes than steel, despite getting more durable in colder temperatures. However, it is easier to mold aluminum into whatever shape you want. If you need an industrial material that is more workable than durable, then aluminum is the right choice.

Weight

The strength of steel partly comes from its superior weight and density. Steel is over 2.5 times denser than aluminum. Compared to concrete, steel is around 60% lighter. That makes it a better option for large constructions that need rigid foundations. The weight and strength of steel can contribute to the overall integrity of an entire structure.

Aluminum is almost one-third of the weight of steel. This limits its capabilities when it comes to toughness, but it opens up avenues in different applications. Because of its weight and superior strength relative to other materials, aluminum is used in aircraft instead of steel.

Corrosion Resistance

One of the greatest advantages of aluminum is its ability to resist corrosion. The oxidation process that turns iron into rust does not work with aluminum. After the chemical process, aluminum oxide will just continue to stick to the metal and shield it from decay, as opposed to oxidation in other metals which will promote its decay. Sometimes, when aluminum is oxidized, the surface will pit and start to turn white.

Steel, with the exception of stainless steel, is vulnerable to decay through oxidation. If you want to extend the life of carbon steel, especially if it’ll be used in a moist or damp environment, it should be painted and treated after being spun. You would need to give it a zinc coating through the galvanizing process to protect it from such corrosion.

Cost

If you’re deciding between these two metals for your project, it’s important to be updated on the costs of each. The cost of both metals is always changing — it largely depends on the supply, demand, and other economic factors in the world. But in general, you can expect that, as raw materials, steel usually costs less than aluminum, over three times less. Assembly costs make aluminum 20-30% more expensive than steel. Still, it’s best to make specific inquiries about costs before making a final decision.

Applications

Considering their key differences, steel and aluminum have different places in the industry. Here are some of the ways that steel and aluminum can be used:

Construction: Construction projects often need stronger and bigger parts to work with. Steel is very useful in this industry, and you’ll see them in skyscrapers, railways, stadiums, and other huge buildings. They are found in the foundations of the buildings and even in the tools used. For the lighter and more intricate parts, like staircases, aluminum is used.

Transportation: The transportation industry uses steel for the majority of a vehicle’s parts and for structures that need durable materials like rails, runways, anchors, and marine vessels. Aluminum shines in the aerospace aspect of transportation as over 90% of aircrafts and spacecrafts are made of aluminum alloys.

Energy: Steel structures are necessary for almost any type of power that we have. Coal, nuclear, wind, electric — they all require plants or generators to work efficiently. Because of its thermal conductivity, aluminum is a good alternative to copper as transmission wires.

Key Takeaway

The thing to remember about the steel vs aluminum debate is that you have to consider their place in whatever industry you need them for. They each have their own applications almost everywhere, so just factor in their specific function before making a choice.

No matter what you want to use your steel for, it’s best to use high-quality metal products. Here at Metal Exponents, we provide the finest grade of steel products to contractors and construction companies all over the Philippines. You may take a look at our products here, or contact us for any questions!