Understanding Steel Plate Prices in the Philippines: Key Factors that Influence Costs

What are the key factors that influence the costs of steel plate prices?

- Raw material costs

- Import duties and taxes

- Global supply chain issues

- Market demand and construction activity

- Steel quality and specifications

Overview

- This article explores the critical factors influencing steel plate costs in the country.

- These include fluctuations in global raw material prices, import duties and taxes, supply chain disruptions, market demand driven by construction activity, and the quality and specifications of steel plates.

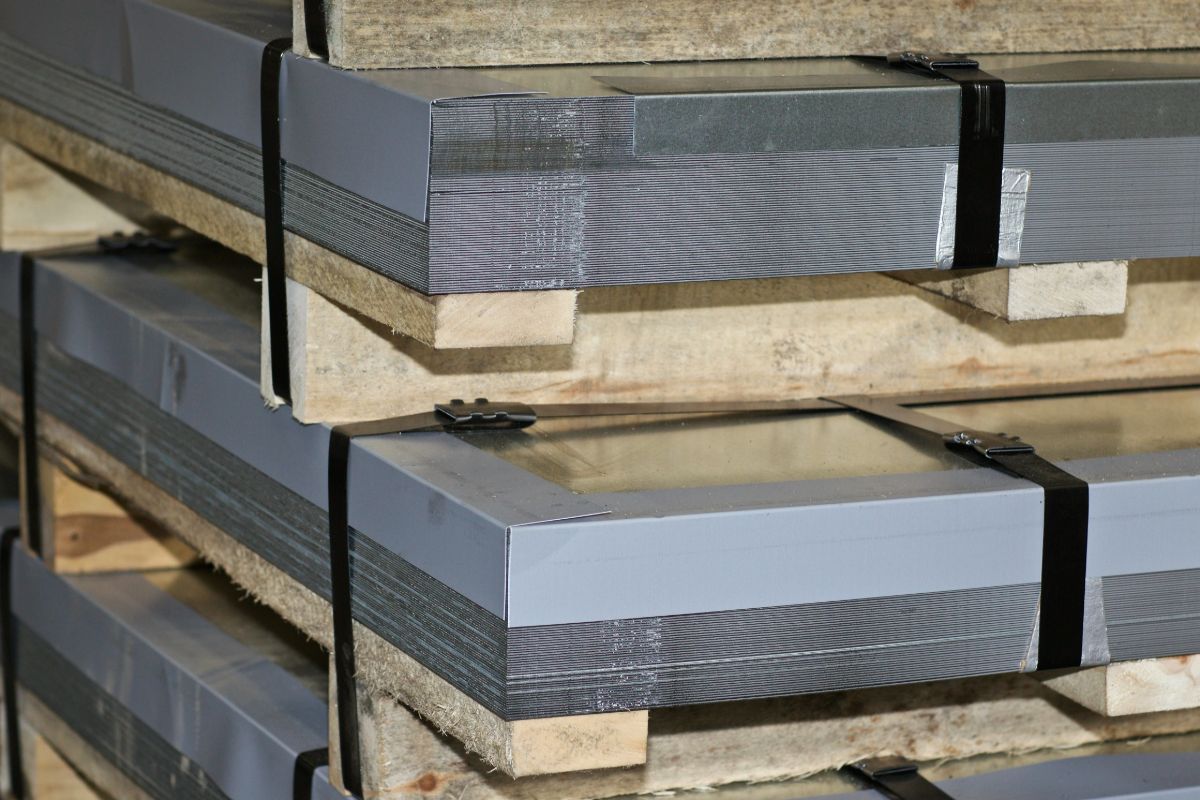

Steel plates are large, flat pieces of metal used in various industries, including construction, manufacturing, and shipbuilding, due to their strength, durability, and versatility. They come in various grades, sizes, and specifications, making them suitable for different structural and industrial applications.

At Metal Exponents Inc., we provide premium-quality steel plates that cater to a wide range of industries, ensuring that your construction projects have the best materials for durability and performance.

By understanding the key factors that affect steel plate prices in the Philippines, you can make more informed purchasing decisions, ensuring both cost-effectiveness and quality.

Raw Material Costs

Key raw materials used in steelmaking include iron ore, coking coal, and limestone. The global market prices of these materials are subject to fluctuations driven by supply and demand, mining production levels, and international trade policies.

For instance, if there’s a disruption in the supply of iron ore due to geopolitical tensions or natural disasters in major exporting countries like Australia or Brazil, the scarcity will drive up its price. This causes steel manufacturers to face higher production costs, which are then passed on to buyers in the form of increased steel plate prices.

An example of this impact can be seen in the recent surges in iron ore prices during 2021, driven by high demand from China and disruptions in mining operations due to the pandemic. This resulted in higher steel prices globally, including in the Philippines, as local suppliers rely heavily on imported raw materials.

Import Duties and Taxes

These costs are government-imposed tariffs on goods entering the country, aimed at protecting local industries and generating revenue. For steel plates, import duties typically range from 3% to 15%, depending on the product’s classification under the Philippine tariff code.

A 12% value-added tax (VAT) is also applied to the landed cost, which includes the product price, freight charges, and insurance. These fees increase the overall cost of imported steel, which suppliers often pass on to buyers. The impact of these taxes is especially pronounced when global steel prices fluctuate.

For instance, during periods of high demand or supply chain disruptions, the base cost of steel increases, and so do the duties and taxes calculated on the landed cost. This cascading effect makes steel plates more expensive for local businesses.

On the other hand, any reduction in tariffs or tax exemptions for specific industries can lower prices, providing relief to the construction and manufacturing sectors.

Global Supply Chain Issues

The Philippines imports steel plates primarily from major global suppliers, such as China, Japan, South Korea, and India. These supply chains are susceptible to disruptions caused by various factors, including port congestion, shipping delays, natural disasters, or geopolitical tensions.

When such disruptions occur, transportation and logistics costs rise, which directly increases the landed cost of imported steel plates. These additional costs are often passed on to buyers, driving up steel plate prices in the local market.

As a result, businesses in the Philippines face fluctuating prices and limited availability, forcing them to pay a premium to secure steel plates for construction or manufacturing needs.

Market Demand and Construction Activity

As demand for steel plates surges, often driven by infrastructure projects and construction booms, prices tend to rise. In contrast, a lull in construction activity can lead to a drop in demand, placing downward pressure on prices. This relationship is particularly evident in the Philippines, where ongoing infrastructure projects, supported by government initiatives like the “Build, Build, Build” program, have kept demand strong.

For example, in the first half of 2023, the country’s long steel demand, including materials for structural applications like plates, rose by 400,000 metric tons, a 14% increase from the previous year, driven by construction projects and urbanization.

Steel Quality and Specifications

The quality and specifications of steel plates are significant factors that influence their price because higher-grade materials often come with superior durability, strength, and resistance to environmental factors like corrosion.

High-quality steel plates may cost more initially but offer long-term savings by reducing the need for frequent replacements and repairs, especially in demanding applications, such as construction, shipbuilding, or heavy machinery.

Specifications also play a major role in determining the price of steel plates. These include the plate’s thickness, dimensions, tensile strength, and added features, such as heat treatment or alloying elements (e.g., chromium, nickel, or manganese) to enhance performance.

Plates that meet stricter international standards, such as ASTM or JIS, are more expensive due to the precision manufacturing and testing processes involved.

Key Takeaway

Understanding steel plate prices in the Philippines is crucial for anyone in industries, such as construction, manufacturing, or engineering, where steel is a fundamental material. Knowing these key elements can help you make informed decisions about budgeting and procurement, ensuring that the materials you invest in are cost-effective while meeting the technical and durability requirements of their projects.

Don’t let fluctuating steel prices or material quality impact your project’s success. Contact us today to discuss how our expert team can provide the perfect steel solutions for your next project. Let’s ensure your work stands the test of time with the best materials in the industry.