Why Choosing 304 Stainless Steel Over 204 Matters for Long-Term Durability

Why choose 304 stainless steel over 204?

- Corrosion Resistance

- Higher Alloy Content

- Versatility

- Temperature Resistance

- Hygienic Properties

Overview

- This article explores the benefits of choosing 304 stainless steels over 204, including enhanced corrosion resistance, higher alloy content, and versatility for various applications.

- Thanks to their high chromium and nickel composition, they provide excellent corrosion resistance.

- Their reliability and durability are pivotal in those industries seeking steel with temperature-resistant and optimal hygiene qualities, such as power generation, automotive, food processing, and pharmaceutical manufacturing.

When selecting the right stainless steel for your project, the choice between 304 and 204 stainless steels can be a crucial decision. These grades have their unique properties, however, there are compelling reasons why you should choose 304 stainless steels over 204.

This article explores their advantages, including their resistance to corrosion, higher alloy content, versatility, temperature resistance, and hygienic properties. So, let’s dive in and discover why 304 stainless steel is the preferred choice in many applications.

Corrosion Resistance

The 304 stainless steel’s high percentage of chromium and nickel contributes to its enhanced corrosion resistance. For instance, chromium forms a passive protective layer on the surface of the steel which obstructs the corrosion, while nickel further improves corrosion resistance and provides stability at both high and low temperatures.

The specific environment and intended application should always be considered when choosing between stainless steel grades. It’s due to the fact each grade may have distinct benefits based on factors such as temperature, chemical exposure, and mechanical stress.

If corrosion resistance is a critical requirement for your project, choose the 304 stainless steels for their higher performance in harsh conditions.

Higher Alloy Content

The alloy composition of 304 stainless steel typically consists of around 15% chromium. This forms a protective passive oxide layer on the surface. On the other hand, its 8% nickel improves the steel’s ductility. It also contributes to enhancing the strength at both high and low temperatures.

Their small amount of carbon is usually kept low (less than 0.08%) to maintain its corrosion-resistant properties. Other elements such as manganese, silicon, and sulfur may be present in small quantities to improve specific properties or aid in the manufacturing process.

Versatility

The remarkable corrosion resistance of 304 stainless steel makes it a versatile choice for various applications that require durability. It can withstand exposure to acids, chemicals, and even corrosive saltwater, which makes it ideal for environments where resilience is crucial. This is why it is widely used in industries such as kitchen appliances and food processing equipment, where corrosion resistance is essential for hygiene and reliability.

In addition to industrial settings, 304 stainless steel is also popular in the architectural sector. It offers a strong and visually appealing solution for structures that face diverse environmental elements.

Temperature Resistance

304 stainless steel belongs to the austenitic family of stainless steels, which exhibit excellent heat resistance. They have a face-centered cubic crystal structure, which provides stability and retains mechanical properties at elevated temperatures.

In various industrial processes that involve high-temperature conditions, this steel grade is known for its reliability and durability. It can retain strength and stability when exposed to heat stress, making it a popular choice in applications where thermal endurance is crucial, including power generation plants, automotive exhaust systems, aerospace applications, and more.

Hygienic Properties

The high nickel content in 304 stainless steel offers an important quality—the ability to maintain a smooth and easily cleanable surface. This is particularly crucial in industries like food and pharmaceuticals, where hygiene standards are extremely important.

On the other hand, their smooth surface, thanks to their nickel composition, simplifies the cleaning process and reduces the potential for bacterial growth. This promotes a sanitary and uncontaminated environment in applications, where strict cleanliness standards are essential, such as food processing and pharmaceutical manufacturing.

Therefore, choosing 304 stainless steel goes beyond mere material selection in these fields. It becomes a strategic decision to ensure optimal hygiene and product safety.

Key Takeaway

The choice between 304 and 204 stainless steel holds profound implications for long-term durability across various applications. Their robust attributes collectively reinforce the idea of why you should choose 304 stainless steel over 204. They’re not just a durable option but a strategic investment in reliability, resilience, and longevity.

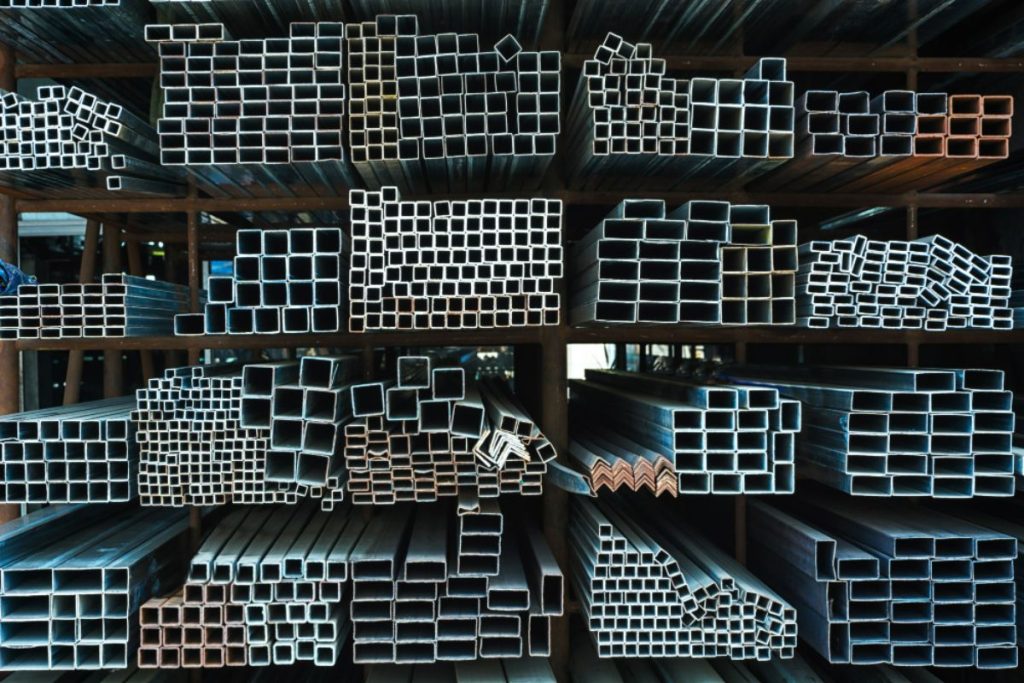

Are you in need of high-quality stainless steel for your projects? Look no further! Metal Exponents is proud to offer our imported steel products in the Philippines. We have a wide range of sizes and forms available, tailored to meet your specific requirements. Our team of experts will guide you in selecting the right grade and assist you in making informed decisions.

Don’t compromise on quality! Contact us today to learn more about our 304 imported steel product offerings.