Key Characteristics That Differentiate Stainless Steel Grades

What are the characteristics that differentiate stainless steel grades?

- Alloy composition

- Chromium content

- Nickel content

- Molybdenum content

- Carbon content

- Heat treatment

- Microstructure

- Corrosion resistance

- Mechanical properties

- Formability and weldability

Overview

- This article explores the importance of alloy composition, including chromium, nickel, molybdenum, and carbon content, in determining the properties of stainless-steel grades.

- You’ll understand the significance of heat treatment, microstructure, and mechanical properties in tailoring stainless steel for specific applications.Discover how formability, weldability, and corrosion resistance vary among different

- stainless steel grades and how these influence material selection for efficient fabrication and long-term performance.

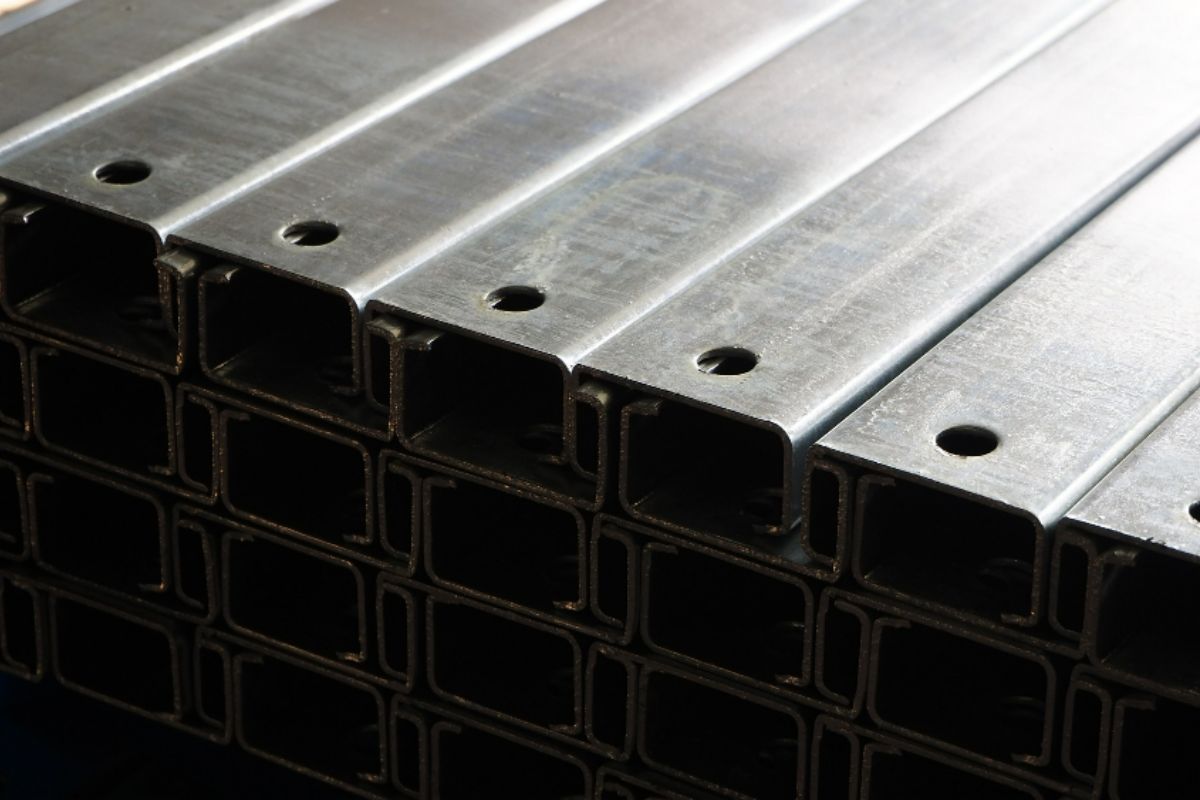

Stainless steel, valued for its durability and corrosion resistance, spans a range of grades tailored to diverse industries. Each grade, with a unique alloy composition and microstructure, offers specific advantages.

This article uncovers the characteristics that differentiate stainless steel grades. From alloy composition to chromium content, nickel, molybdenum, carbon, and beyond, understanding each is vital for choosing the right grade for your engineering, manufacturing, and architecture projects.

Alloy Composition

Stainless steel, composed of iron, chromium, nickel, and other alloying elements, offers a wide range of grades with varying proportions of these components. These unique combinations determine crucial properties such as corrosion resistance, strength, and durability.

Each stainless-steel grade is specifically engineered to meet the unique demands of different industries, ensuring a specialized balance of attributes for specific applications.

Chromium Content

Chromium is essential in stainless steel for bolstering corrosion resistance. The minimum chromium content for the stainless designation is approximately 10.5%, forming a protective oxide layer.

However, different grades may surpass this threshold. This variability enables tailoring stainless steel for diverse applications, with higher chromium content correlating with increased durability in harsh conditions.

Nickel Content

Nickel is a key contributor to the corrosion resistance and toughness of stainless steel. In certain grades, like austenitic stainless steels, the higher nickel content is deliberately added for increased corrosion resistance and improved formability during manufacturing.

This strategic use of nickel enhances the material’s durability in corrosive environments while facilitating easier shaping in various applications.

Molybdenum Content

The addition of molybdenum serves a crucial role in enhancing the steel grades’ corrosion resistance, particularly in challenging environments characterized by exposure to chemicals and saltwater.

Molybdenum augments the material’s ability to withstand corrosive agents, providing an extra layer of protection in harsh conditions. It also helps in addressing specific environmental challenges and extending the overall durability and reliability of stainless steel in demanding applications.

Carbon Content

The carbon content in stainless steel determines its hardness and strength. Opting for lower carbon content is advantageous in situations requiring welding and forming, facilitating easier manipulation.

In contrast, martensitic stainless steels may feature higher carbon content to enhance hardness, making them well-suited for applications where hardness is a key consideration.

Heat Treatment

Heat treatment is essential in tailoring the stainless steel’s structure, hardness, and resilience to meet the requirements of diverse applications.

For instance, annealing, quenching, and tempering are strategic steps employed in the heat treatment process. This allows for precise control over the material’s mechanical characteristics and ensures optimal performance in a variety of industrial settings.

Microstructure

Stainless steel’s versatility stems from its ability to adopt different microstructures, each offering distinct properties. Austenitic microstructures, as seen in grades 304 and 316, provide remarkable corrosion resistance and formability, making them suitable for industries like chemical processing.

The selection of a specific microstructure enables tailored solutions, allowing stainless steel to excel in diverse industries by meeting specific performance and environmental demands.

Corrosion Resistance

Corrosion resistance is a crucial factor in stainless steel grades, with certain grades excelling in specific environments such as marine, acidic, or high-temperature conditions.

While all stainless steels possess corrosion-resistant properties, their varied compositions make them particularly well-suited for distinct applications, ensuring durability and reliability in diverse settings.

Mechanical Properties

They also vary in strength, hardness, ductility, and toughness, with their mechanical properties influenced by factors like alloy composition, heat treatment, and manufacturing processes. The alloy composition sets the foundation, while heat treatments and manufacturing processes further refine the material’s characteristics.

This interplay allows for the customization of stainless steel grades to meet specific application requirements, whether for structural strength, wear resistance, or malleability.

Formability and Weldability

Stainless steel grades vary in formability and weldability, influenced by factors like alloy composition and microstructure. While some, such as austenitic stainless steels, excel in both formability and weldability, others, like martensitic grades, may pose challenges requiring specialized techniques.

This understanding aids in selecting the right grade for specific applications, ensuring efficient fabrication without compromising structural integrity or performance.

Key Takeaway

The characteristics that differentiate stainless steel grades, encompassing various factors, allow for tailored solutions across a broad spectrum of applications. Their lasting importance in addressing the diverse needs of industries is underscored by the versatility and customization opportunities offered through these characteristics.

Metal Exponents Inc. has been importing the world’s finest steel into the Philippines, which focuses on durable products, reliable delivery, and competitive rates. To check our products, you can contact us today!