5 Stainless Steel Grain Finish Applications

What are the applications of a stainless steel grain finish?

- High-traffic Areas

- Architectural Applications

- Food and Beverage Manufacturing

- Commercial Equipment and Machinery

- Stainless Steel Jewelry

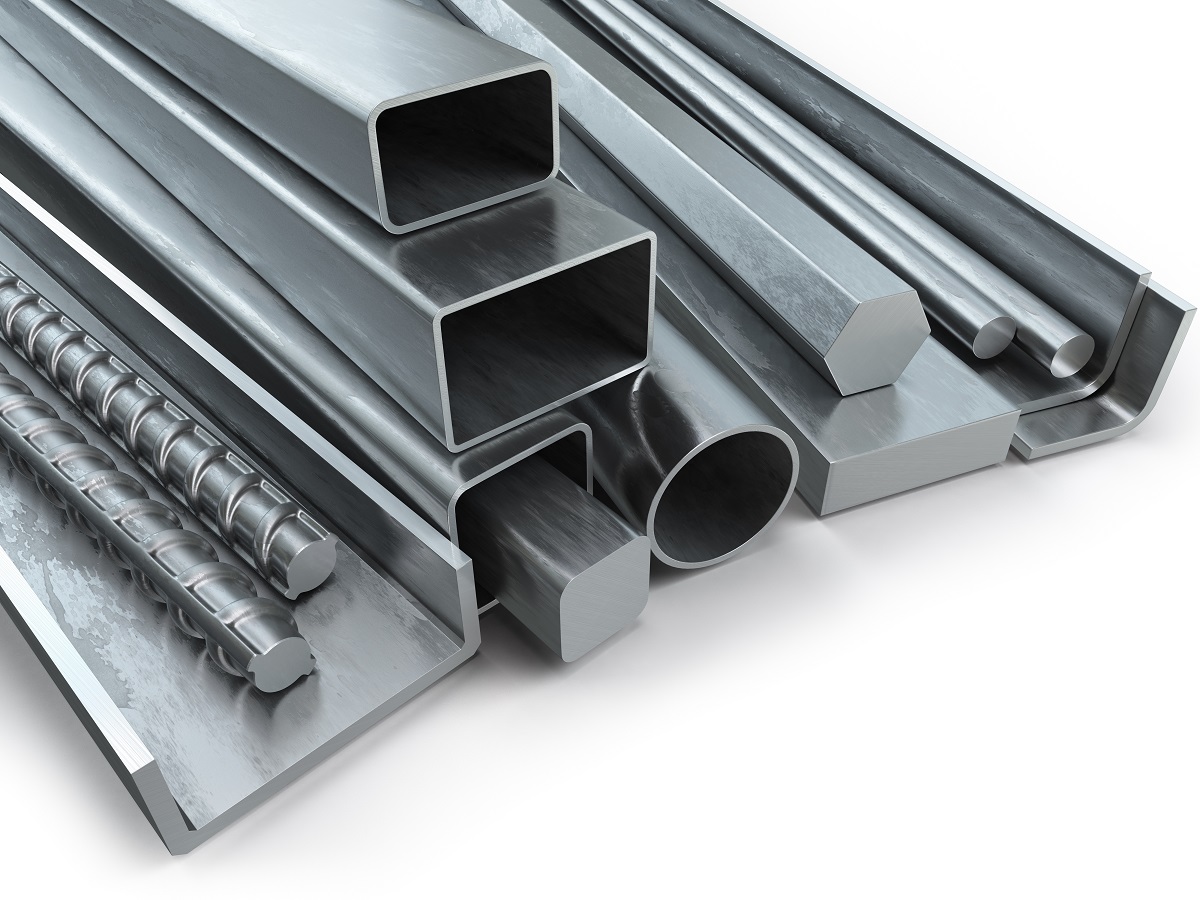

Choosing the right finish for your stainless steel products can be crucial in ensuring that they can meet the specific needs of your application. With the wrong finish, your stainless steel may experience faster erosion and safety issues. When it comes to a grain finish, it is most commonly used for its appearance, durability, and resistance. Here are some examples of applications of stainless steel grain finish.

What is a stainless steel grain finish?

A grained finish is also known as a ‘brushed’ finish. It is achieved by a no. 4 finish, but some consider a no. 3 finish to fall under the same category. A grained finish can vary based on your supplier, and even from batch to batch.

It is characterized by short, parallel lines that run along the length of the metal. These lines are made by mechanically polishing them with gradually finer abrasives. Depending on the requirements of the finished product, this finish can be made with abrasives between 120 to 320 grit. Higher grit creates a finer pattern and a more reflective surface.

Grain finishes have a distinctive look and muted luster due to the pattern on their surface. This pattern helps to reduce the reflectiveness of the material but also reduces its corrosion resistance. This is because the pattern has more grooves that can retain moisture, making it more susceptible to rust.

High-traffic Areas

Using a grain finish is common for stainless steel parts used in the construction of high-traffic areas. Using this finish provides the metal with increased resistance to wear and tear, and helps it to retain its original look despite heavy use.

More reflective or buffed-out surfaces will quickly lose their sheen in this application. Constant use, footfalls, and other impacts can create noticeable dents and scratches on these finishes. However, with a grain finish, it already has a dull sheen that helps to hide any visible damage on its surface.

There are countless grain finishes used in residential and commercial construction. Due to its resistance to scratches and wear, a grain finish is perfect for stainless steel products on escalators, elevators, handrails, control panels, hospital surfaces, and more.

Architectural Applications

Stainless steel is widely used in many building applications for its ideal strength-to-weight ratio, durability, and rust resistance. This creates the perfect metal products for architectural designs, for both residential and commercial buildings.

Adding onto the metal’s natural and manufactured properties, a grained finish also improves the metal’s impact and scratch resistance. It also reduces the surface’s reflectivity, which can be ideal for outdoor spaces, or rooms that are exposed to plenty of natural sunlight.

All in all, a grain finish stainless steel product is suitable for decorative applications, where the appearance of the metal needs to be easily maintained and less reflective. Examples of this are handrails, outdoor furniture, metal roofing, and balustrades.

Food and Beverage Manufacturing

The grain on a stainless steel surface is more susceptible to retaining moisture and particulates, which makes it easier for bacteria to grow and multiply. Due to this, it is unsuitable for making machine components that directly come into contact with food and beverages during production.

Though grain finishes are not recommended for the manufacturing of high-grade food or beverage machines, they can be used for making the protective panels and surfaces around this machinery. This is because a grain finish offers a sturdy and durable surface that is perfect for protecting workers and other employees in this industry.

Commercial Equipment and Machinery

Another common use of this finish can be found in our own homes. You may have noticed that your stainless steel fridge has a dull, brushed look. This is one popular application of the grain finish. The reason why most fridges today use this finish is that polished steel can pick up fingerprints, oil residue, and debris in the kitchen. However, with a grain finish, the appearance of such dirt and oil will be significantly reduced.

Stainless steel in general is favored in commercial machinery (such as kitchen appliances) due to its high durability and easy-to-clean surfaces. Grain finishes in particular are favored for these appliances. They help increase durability, are unlikely to damage the product, and are still easy to clean. As such, a grain finish offers all of the benefits of stainless steel and with fewer expenses compared to other mechanical and chemical finishes.

Stainless Steel Jewelry

Stainless steel jewelry is also a popular application for this metal. Tarnish resistant, bright finishes, hypoallergenic properties — all qualities that make it a popular material for jewelry. Furthermore, jewelers can use grain finishes to create beautiful wire-brushed marks on finished pieces. In this application, the metal is gently worked to create fine lines that are only visible when you look closely. This finish also helps improve the piece’s resistance to tarnishes and scratches, making it a more durable jewelry piece.

Key Takeaway

The applications of stainless steel with a grain finish show that this material is a cost-effective solution for many things ranging from architectural design to jewelry. It is the perfect metal for any product that needs strength, durability, and aesthetic appeal.

Looking for high-quality, grain-finished stainless steel for your project? Metal Exponents can help you with that. Contact us today to begin discussing your project, and how our products and services can help you achieve your requirements.