Factors Influencing Steel Matting Prices: What You Need to Know

Overview

- Steel matting is an essential material in construction, used for reinforcing concrete and providing structural stability in projects like foundations, roads, and floors.

- Its price is influenced by several factors, including material quality, market demand, manufacturing costs, and transportation expenses.

- At Metal Exponents Inc., we offer high-quality steel products, backed by years of industry experience and a commitment to transparent pricing and reliable delivery.

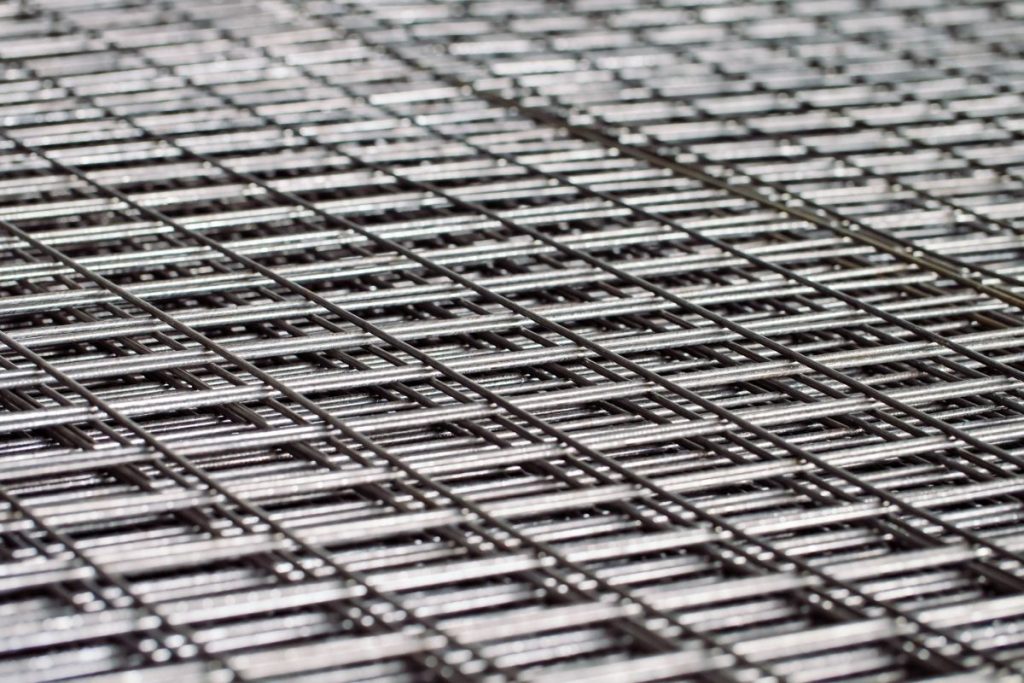

Steel matting is a vital material in construction, composed of a network of steel bars welded together. It reinforces concrete, distributes loads efficiently, and prevents cracks—adding strength and stability to foundations, floors, and roads.

In this article, we’ll explore the key factors influencing matting prices, helping you secure high-quality materials while staying within your budget. At Metal Exponents Inc., we’re committed to providing reliable, top-notch construction supplies that meet your project’s needs. With our competitive pricing and dedication to quality, we help ensure your project stays on track and within budget.

Key Factors Affecting Steel Matting Prices

The price of steel matting is influenced by several key factors. Understanding these elements helps ensure you get the best quality steel matting that fits within your project’s budget.

Material Type and Quality

High-quality steel matting, made from durable materials like carbon steel or stainless steel, tends to be more expensive due to its superior strength, corrosion resistance, and longer lifespan. This is ideal for demanding projects, offering enhanced safety and minimal maintenance costs.

On the other hand, low-quality steel matting, often made from cheaper materials or low-grade steel, may come at a lower initial cost, but can lead to rusting, weakening, and frequent repairs over time, making it less cost-effective option in the long run.

Market Demand and Supply Fluctuations

When demand for construction project rises, the need for steel matting increases, which can drive up prices due to limited supply. Conversely, during economic slowdowns, reduced construction activity can lower demand, leading to price stabilization or even a decline.

The Philippines’ construction market is projected to grow between 2024 and 2028, fueled by large-scale infrastructure projects and increased foreign direct investment. As demand surges, prices for steel products, including steel matting, are likely to rise as suppliers strive to meet the growing construction needs.

Manufacturing and Production Costs

Costs involved in production, such as raw materials, labor, equipment, and energy, all play a role in determining the price of steel matting. When raw material prices, like steel, fluctuate or labor costs increase, manufacturers often pass these additional expenses onto consumers.

Additionally, the efficiency and technology employed in the production process significantly influence overall expenses. While more advanced and automated processes can reduce costs in the long term, the initial investment in machinery can raise prices.

As a result, the price of steel matting is closely tied to the overall production costs, meaning that price hikes in any area of the manufacturing process can lead to higher costs for buyers.

Transportation and Logistics Costs

Steel materials are heavy and bulky, which makes their delivery more costly. The farther the distance between the supplier and your project site, the higher the transportation costs will be, which adds to the overall price of steel matting.

Factors such as fluctuating fuel prices, tight delivery timelines, and specific handling requirements can further influence these transportation costs.

Tips for Getting the Best Value for Steel Matting

Here are some valuable tips to help you get the best value for steel matting in your construction projects. By following these strategies, you can optimize your investment and ensure you’re securing high-quality materials at a fair price.

Compare Multiple Suppliers

You can evaluate each supplier based on product quality, price, delivery times, and customer service. Look at the overall cost, including hidden fees like transportation and handling charges, and compare the value you’re getting for the price.

It’s also important to check the supplier’s reputation and experience to gauge reliability. Don’t hesitate to ask for samples, inquire about certifications, or request quotes from different suppliers to make a direct comparison.

Prioritize Quality over Low Prices

Cheaper options often come with compromised strength and durability, making choosing quality over low prices essential. To ensure you’re getting the best value, focus on suppliers that offer certified, high-quality steel matting that meets industry standards, even if it comes at a slightly higher price.

This investment in quality ensures that the steel matting will perform well under load, withstand environmental conditions, and reduce the need for repairs or replacements in the future.

Negotiate for Bulk Orders and Transparent Pricing

When you purchase in larger quantities, you may secure discounts, as suppliers are often willing to offer better pricing for bulk buyers. To do this, reach out to suppliers and inquire about any volume-based discounts they offer.

For example, if you’re working on a large-scale construction project, you could negotiate a deal where purchasing several tons of steel matting lowers the per-unit cost.

Why Choose Metal Exponents Inc. for Your Steel Matting Needs?

We at Metal Exponents Inc. understand that finding reliable, high-quality steel matting at competitive prices is essential for your project’s success. With decades of industry experience, we take pride in offering a wide range of durable and certified steel products that meet stringent industry standards.

Our transparent pricing structure ensures you know exactly what you’re paying for, while our dependable logistics network helps deliver your materials on time.

Key Takeaway

From the quality of the steel to transportation costs and supplier reputation, each element plays a vital role in determining the final price. By considering these factors influencing steel matting prices, you can ensure you’re getting the best value while maintaining the quality and reliability of your structure.

If you’re looking for a trusted partner that provides high-quality steel with transparent pricing and reliable delivery, Metal Exponents Inc. is here to support your project needs. Contact us today to learn more about how we can help you achieve your goals efficiently and cost-effectively.