Black Steel Pipes 101: Basic Things You Need to Know

What are the basic things to know about black steel pipes?

- It’s material composition

- Its resistance to corrosion

- Its versatile applications

Overview

- Black steel pipes are primarily made from carbon steel, an iron-carbon alloy with trace elements

- While black steel pipes exhibit a notable degree of resistance to corrosion, they are not as corrosion-resistant as galvanized pipes. The absence of a protective zinc layer makes them more susceptible to rust.

- Black steel pipes find versatile applications across multiple industries. They are commonly used in water and gas distribution systems due to their durability and corrosion resistance.

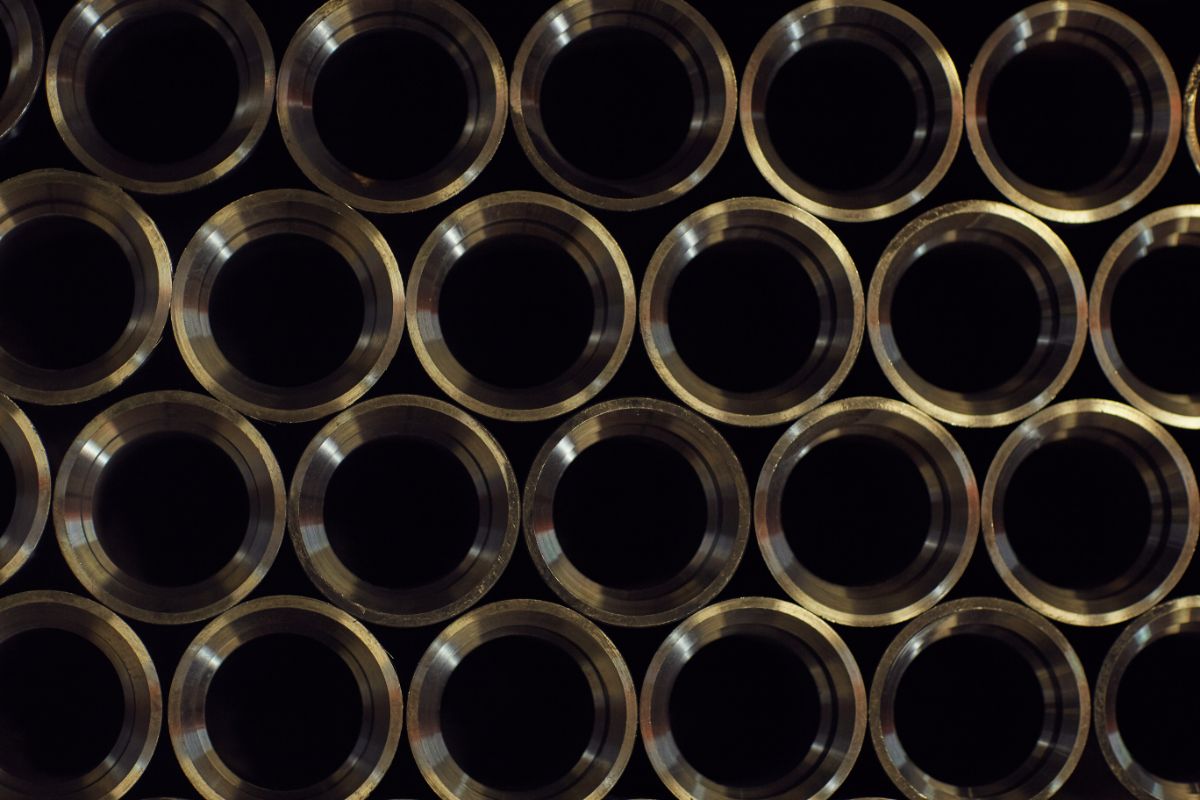

Carbon steel pipes, often referred to as black steel pipes, are a fundamental component in various industries, offering a sturdy and versatile solution for countless applications. Whether you’re involved in construction, plumbing, or manufacturing, understanding the basics of these pipes is essential.

In this comprehensive guide, we’ll delve into the essential knowledge you need to navigate the world of carbon steel pipes, often referred to as black steel pipes, with confidence. From their composition and manufacturing process to their common applications and maintenance tips, we’ll cover it all. So, whether you’re a professional seeking to refresh your understanding or a newcomer eager to learn, join us on this journey through the fundamentals of carbon steel pipes

It’s Material Composition

Black steel pipes are typically made from carbon steel. Carbon steel is an iron-carbon alloy, primarily composed of iron and carbon, with trace amounts of other elements. These pipes stand out due to their unique composition. Unlike galvanized steel pipes, they lack a protective zinc coating, resulting in their distinctive dark appearance.

This uncoated surface affects both their aesthetics and suitability for various applications. Therefore, choosing the right contractor for these pipes is crucial, especially for projects in the Philippines.

Its Resistance to Corrosion

While black steel pipes demonstrate a notable degree of resistance to corrosion, it is important to understand that they do not possess the same corrosion resistance as galvanized steel pipes. These pipes can endure the corrosive effects of environmental factors to a significant extent, making them suitable for a range of applications. However, it is crucial to acknowledge that they are more prone to rusting compared to galvanized pipes, primarily because they lack the protective zinc barrier that shields against corrosion.

In specific scenarios where black steel pipes are exposed to particularly demanding or harsh conditions, additional protective coatings may be advisable. These coatings serve to enhance the pipes’ longevity and reinforce their ability to combat corrosion effectively, ensuring their durability in various settings, from plumbing systems to structural applications.

Its Versatile Applications

Black steel pipes boast remarkable versatility, finding use across a wide array of industries and applications. They play a crucial role in water and gas distribution systems, offering durability and corrosion resistance for the reliable transport of these essential utilities.

In the oil and petroleum industry, these pipes are indispensable for safely and efficiently moving vital resources, thanks to their robust construction and resilience.

Furthermore, they serve as foundational components in construction, providing structural support as pillars, beams, or framework elements.

How to Maintain Carbon Steel Pipes

Ensuring the longevity, optimal performance, and safety of carbon steel pipes across diverse applications necessitates diligent maintenance. To this end, we outline crucial steps for proper upkeep:

- Regular Inspection: Conduct routine inspections to identify signs of corrosion, leaks, or damage. Pay attention to joints, fittings, and areas exposed to harsh conditions.

- Cleaning: Remove dirt, debris, and rust from the pipe’s surface using appropriate cleaning methods. For light cleaning, use a wire brush; for heavier rust, employ abrasive methods. Finish with a clean cloth to ensure a smooth surface.

- Coating and Painting: Apply anti-corrosion coatings or paints to protect the pipe’s surface from environmental factors. Rust-resistant coatings like zinc or epoxy can provide an extra layer of defense.

- Proper Storage: When storing carbon steel pipes, keep them in a dry, well-ventilated area to prevent moisture buildup and corrosion. Use wooden supports or racks to elevate them off the ground.

- Regular Testing: Schedule non-destructive testing (NDT) or pressure tests to detect internal corrosion or weaknesses. Address any issues promptly to avoid potential failures.

- Corrosion Prevention: Implement corrosion prevention measures, such as cathodic protection systems or inhibitors, in corrosive environments.

- Thorough Cleaning After Welding: If welding is involved, clean welded areas thoroughly to remove slag and spatter, which can lead to corrosion.

Key Takeaway

In the world of construction, plumbing, manufacturing, and more, carbon steel pipes, often known as black steel pipes, are foundational components. This guide has provided essential insights to help professionals and newcomers better understand these pipes, offering a strong foundation for their applications.

Unlock the potential of imported steel pipes with Metal Exponents, your trusted steel supplier in the Philippines. Contact us today to explore a world of high-quality materials for your next project. Let’s build excellence together.