Everything You Need To Know About Steel Channels

What do you need to know about steel channels?

- What steel channels are

- How steel channels are made

- Why steel is best for metal channels

- Types of steel channels

- Applications of steel channels

Among all the products that you can get from a steel manufacturer in the Philippines such as Metal Exponents, one of the most popular and versatile pieces is steel channels. They come in numerous sizes, shapes, and thicknesses, and can be found in a variety of construction and industrial applications.

But what are steel channels, and how might they be used in your steel project? To help you understand this versatile piece better, we present everything you need to know about steel channels:

What steel channels are

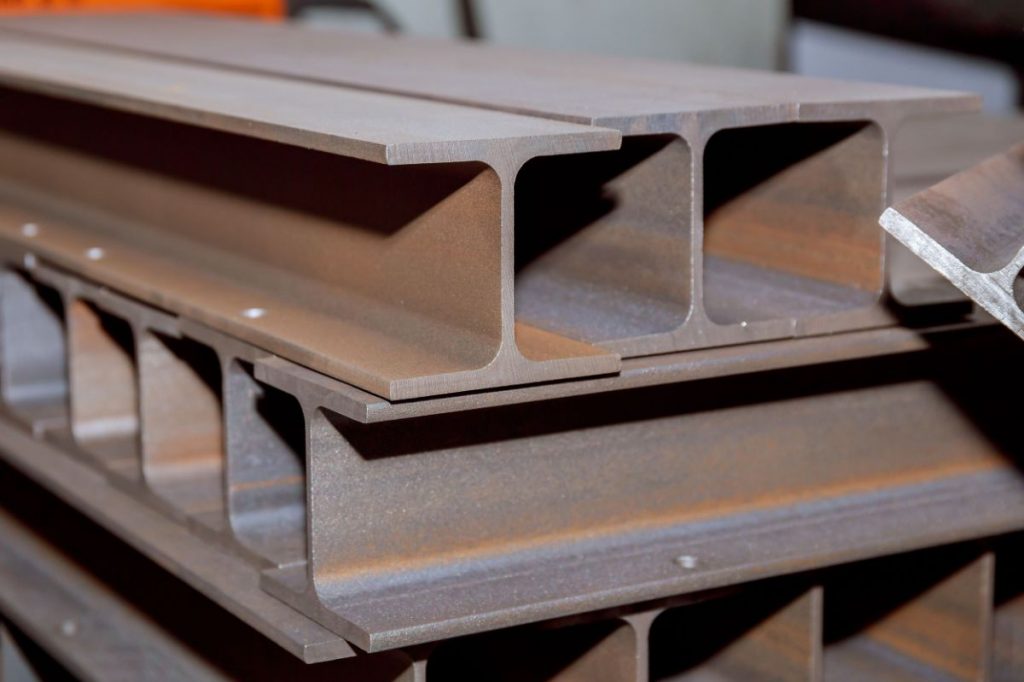

Steel channels are hot-rolled carbon steel, shaped to have a vertical web and two horizontal flanges. The web is typically wide, while the flanges can either be parallel or tapered.

Steel channels have excellent strength and durability, which makes them ideal for steel structures. They are often found in building frames and braces, as well as in supports for a variety of heavy equipment and machines.

Steel channels are also very thick, which allows them to absorb sound and muffle vibrations.

However, these are only just a few of their many possible applications, which are very tough, long-lasting, and have many other great qualities.

How steel channels are made

Steel channels are usually made from hot-rolled mild steel. In this process, a metal strip is fed through a series of rollers — also known as supports. This distorts the strip until the desired shape and form are created. After the shaping is completed, the rolled form is cut to the required length.

The process of creating steel channels is generally quick and low-cost. Steel channels also don’t require any extra processing or finishing steps. This allows steel channels to be mass-produced at an affordable price.

However, there are cases where steel channels will be subjected to extra fabrication steps after being hot-rolled. They can be galvanized after fabrication to improve their durability and corrosion resistance. They can also be drilled or machined to fit the precise specifications of the project. Lastly, they can be welded to create larger or custom forms.

Why steel is best for metal channels

So, why is steel the metal of choice for channels? That is because steel possesses the best mechanical qualities that a channel needs.

Steel is one of the hardest metals that we can use in manufacturing. It has an excellent capacity to tolerate deformation and surface indentation, as well as resist scratching and chipping. Steel’s hardness also helps it provide resistance to common elements in steel structures, such as friction and erosion caused by oil, water, and steam.

Another mechanical property that steel has that makes it the ideal material for channels is toughness. Steel can easily absorb high amounts of energy without risking cracking or rupturing. It can resist strain and heavy loads as well.

Types of steel channels

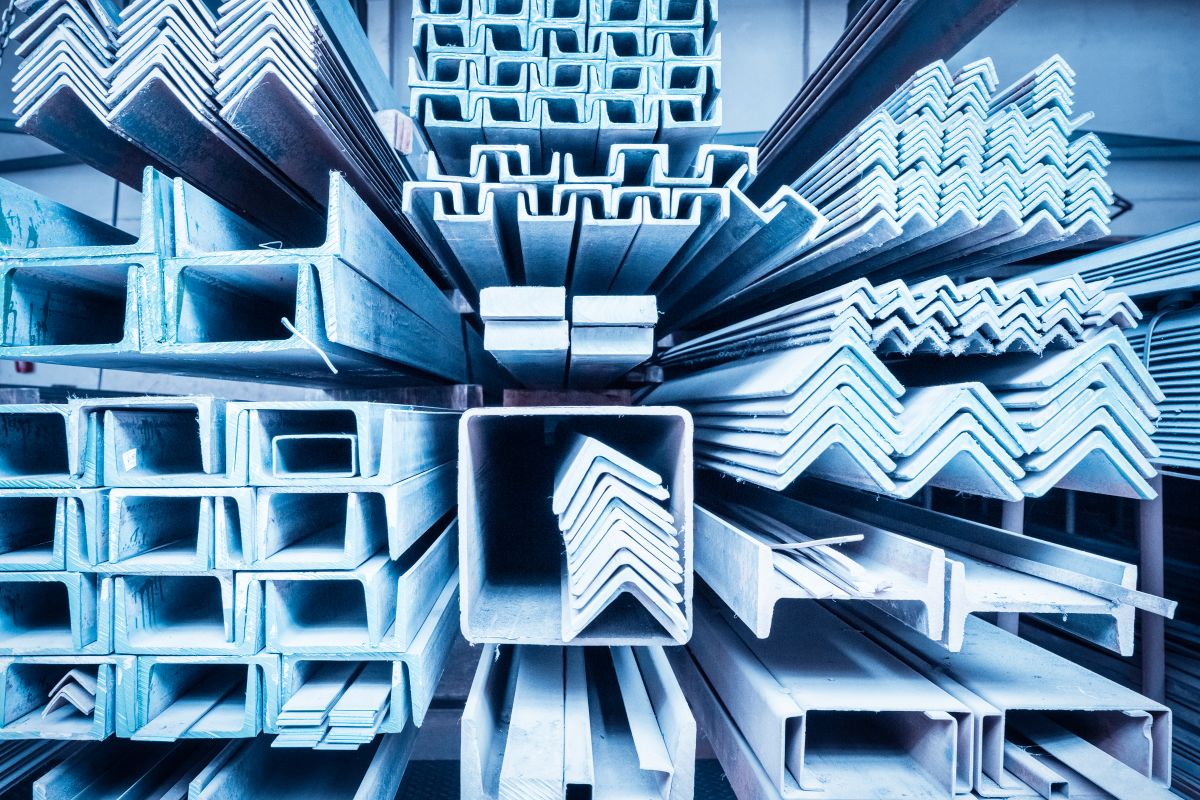

There are many kinds of steel channels that can be shaped during the roll-forming process. The shapes and dimensions needed in a channel are determined by the needs and requirements of the application you intend to use them in.

Here are the most common types of steel channels you can get from a steel manufacturer in the Philippines:

- U Steel Channels — Named for its “U” shape, it consists of a wide vertical web and two tapered flanges. This type of steel channel is generally used for structural metal channels and architectural channels.

- C Steel Channels — Another common form of metal channel, this one is similar in shape to the U steel channel type, except they have two parallel flanges instead of tapered ones. They are often used as support for buildings, walls, roofs, and ceilings.

- Z Steel Channels — Often referred to as purlins, these steel channels are often used in construction as well as DIY projects. You can find them in framing, support, tracks, and similar applications.

- Hat Steel Channel — This steel channel has two horizontal outward flanges, and two vertical flanges, which create an image similar to a hat. Their shape makes them excellent for roof framing.

- J Steel Channel — This shape is achieved by making one of the steel channel’s sides longer than the other. They come in a wide range of sizes and can be tailored to meet specific project needs. The most common forms of a J channel include hemless channels, hemmed channels, and those with a flat part that can be screwed or nailed on.

Applications of steel channels

Steel channels have many uses, from homes to industrial buildings to other metal structures. Some common applications include:

- Constructing walls for warehouses, garages, and other similar structures, wherein they are installed similarly to studs for supporting the building’s vertical load.

- As attachment points for sidings, such as sheet metal. Here, they are run horizontally from pole to pole to create a connecting arm for external and internal wall finishes.

- As rafters for light-duty roofs, where they run from eaves to ridge and provide support for the roof deck.

- As supporting metal for heavy-duty roofs, where steel channels are installed perpendicularly on top of l-beam rafters. This bridges the spaces between the rafters, allowing them to be spaced further apart, while also creating attachment points for the roof deck.

- As strong frames for windows and doors. Channels are attached in four parts, with miter joints on each end to create a flat surface in the opening on which a door or window can be mounted.

- To support hardwood beams in a wood-framed building when extra strength is required. Either the wood beam is placed in a large steel channel, or steel channels are added at the bottom of an existing beam to boost their strength.

- To make car frames. Primary frame rails that run from end to end of the vehicle are usually made from heavy-duty steel channels. Braces and other structural components are made from lighter steel channels.

- In building trailers, such as box trailers, travel trailers, and even recreational vehicles (RVs).

- In commercial and industrial buildings, where they are installed in conjunction with l-beams and other structural steel pieces. In this application, they can be used as studs, braces, girts, and joists.

- They can also be used for railings, bridge trusses, guard rails, stair stringers, and other similar structures in buildings.

Steel channels are a very flexible and versatile steel product, with many uses in structural support — both in light-duty and heavy-duty applications.

Key Takeaway

Now that you know everything there is to know about steel channels, you might be looking to use its versatility, strength, and durability in your project.

If so, work with the top steel manufacturer in the Philippines — Metal Exponents. Our steel channels come in a variety of forms and lengths and can be customized to fit your exact specifications. Send us a message today to get started!