Horizontal VS Vertical Milling Machine: The Key Differences

What are the key differences between horizontal vs vertical milling machine?

- Orientation

- Versatility

- Workload

- Risk of Error

- Cost

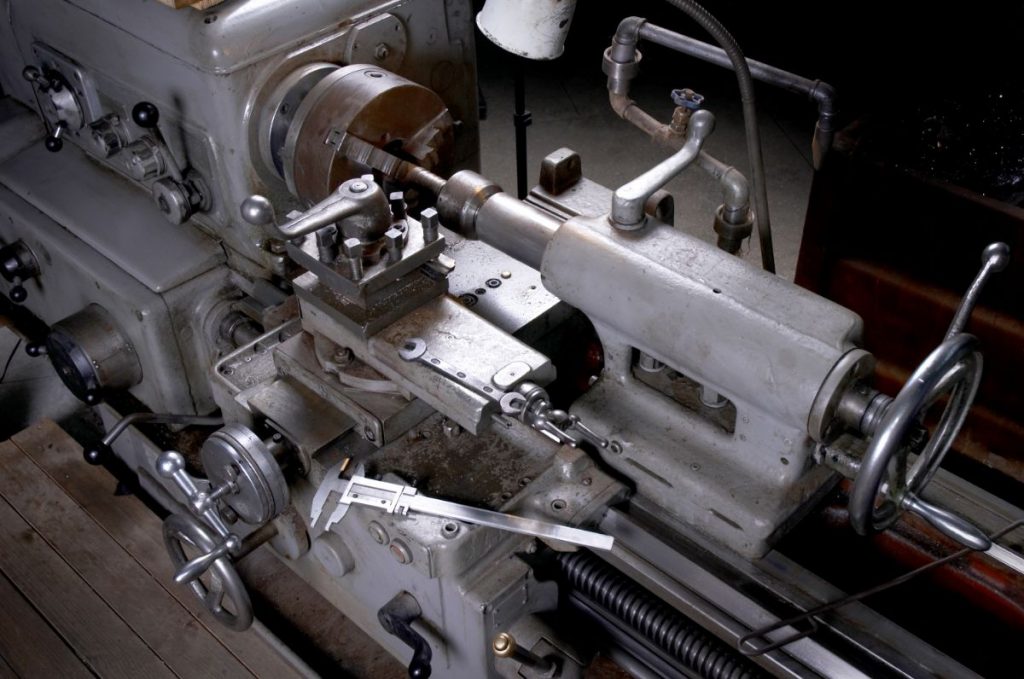

The most common way to remove some parts from the material in metal fabrication is by milling. This process involves a cutting tool that rotates rapidly used on a workpiece that is clamped down on the table. With the tool, you can cut the material into any shape and dimensions that you may want. A milling machine can be oriented horizontally or vertically. There are specific reasons why the two machines are built that way, and fabricators need to know the differences between a horizontal vs a vertical milling machine.

Because this method is widely used, you’ll see milling machines in many metal fabrication workshops. There are even different milling centers dedicated to each type of milling machine. In this article, we’ll talk about what sets each milling machine apart to help you understand how they work and which you should use for your project. Keep reading below to learn more.

Orientation

Let’s start with the basics. The biggest difference is the orientation of the machines, as is evident by their names. The spindle of the vertical milling machine is oriented vertically while the horizontal milling machine has a spindle that is laying down horizontally. This varies the uses of each machine. If you want parts with more detail, it’s better to use the thinner but longer cutting tool of the vertical milling machine. If you want to make deeper cuts into the material, then you should use the horizontal milling machine.

Versatility

Of the two milling machines, vertical milling machines are the more versatile ones. They are easier to use and maneuver to create more shapes and better dimensions. Their versatility is partly because there are two types of vertical milling machines: turret milling machines and bed milling machines. The latter allows the worker to move the table on a perpendicular axis. The former is more preferred and gives more versatility as both the table and the spindle can move. With the help of a worker, it’s easier to create more shapes with the vertical milling machine.

On the other hand, horizontal milling machines are known for their versatility, but they can produce output more than vertical milling machines.

Workload

Horizontal milling machines are more suited to heavier work than vertical milling machines are. They can do the work that is equivalent to what 3 or 4 vertical milling machines can do. This is because horizontal milling machines are generally more powerful than their vertical counterparts. Consistent use of vertical milling machines also reduces the tool life while horizontal milling machines increase the tool life. This is more proof that horizontal machines can do more work than vertical milling machines.

Risk of Error

Nowadays, computer numerical control (CNC) machines are used to ensure the precision and accuracy of fabrication. But that doesn’t mean that operators are no longer needed. Vertical milling machines are set up in a way that gives higher visibility to the operator. And because it’s much easier to see your work, it could also be tempting for workers to make cuts based on their sight instead of measurements. The risk of human error is high for vertical milling machines because of this.

The opposite is true for horizontal milling machines. The placement of the spindle on this machine lowers the visibility. Operators would not be able to see clearly what’s going on with the workpiece. The chance of error here is that workers would not be able to spot any mistakes in the fabrication and stop them right away.

Cost

If you’re trying to decide which milling machine to get for your workshop, then the price is a crucial factor. One reason why vertical milling machines are more popular is that they are the cheaper option. They offer versatility and cost-effectiveness for those who get them. They are attractive for smaller companies because of the low initial price.

However, horizontal milling machines are more productive in the long run despite their higher price tag. Even though there are fewer operators trained to use these machines, a single attentive worker can keep two of these machines running. The processing time is also shorter for horizontal machines, increasing your product output and making your investment worthwhile.

Key Takeaway

It’s a wise move to invest in either a vertical or a horizontal milling machine. Both machines have something to offer to help you in your fabrication processes. But if you’re deliberating between a horizontal vs vertical milling machine, then consider the difference discussed here and the needs of your company to make a final decision.

Another crucial part of metal fabrication is the material that you feed to the machines themselves. To get the finest metal products, try Metal Exponents! We are the leading supplier of top-of-the-line metal products in the Philippines, thanks in part to our international partnerships. If you want to check out the best metal products around, follow this link. Contact us anytime if you’re interested!