9 Benefits of Laser Cutting

What are the benefits of laser cutting?

- Flexibility

- Precision

- Versatility

- Consistency

- Speed

- Automation

- Reduced Finishing Requirements

- Contactless Cutting

- Energy Usage

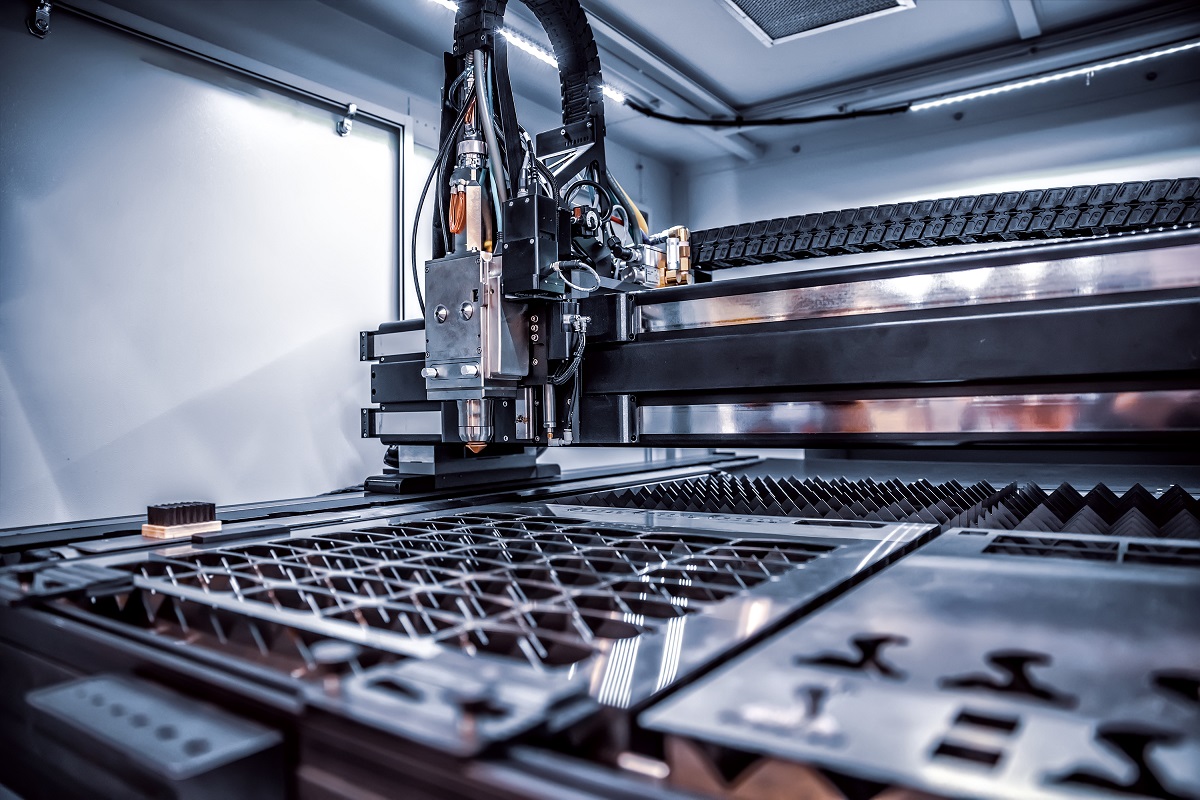

Cutting is one of the most basic and widespread processes in metal fabrication. It’s crucial in shaping simple metal sheets into smaller, more complex parts. There are many different cutting methods that manufacturers use to process metal — but laser cutting is one of the most advanced and offers a long list of upsides compared to others. Read on to learn about the benefits of laser cutting, and how this method can work with your metal project.

Flexibility

Laser cutting does not need tooling or an exchange of tools to achieve separate cuts. They require no hard tools, which means there is no need for tool changeover or sharpening in between cuts. And, the setup you start with is the same setup you can use to cut a variety of shapes within the same material thickness. Laser cutting machines are flexible and can achieve intricate cuts without costly downtime or inefficiencies — even in large production runs.

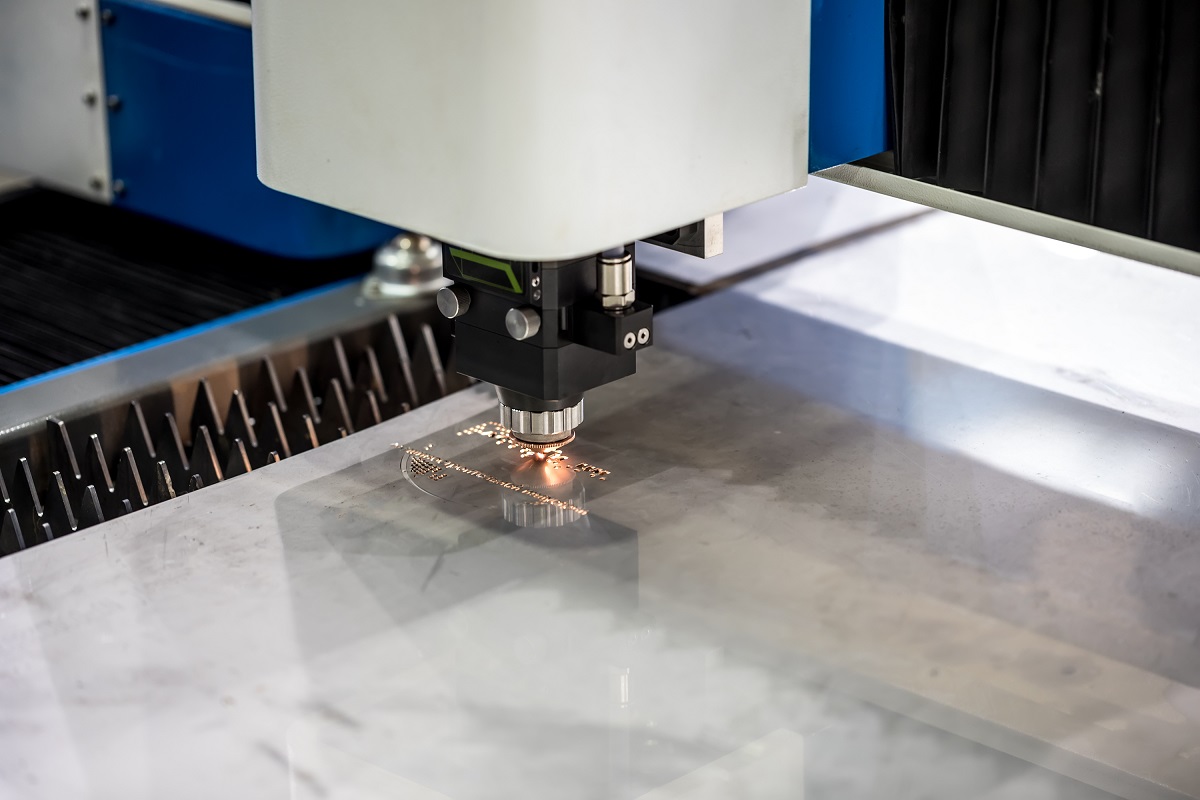

Precision

Accuracy is another advantage that laser cutting offers. When compared to other cutting methods, laser cutting can produce cuts within a smaller margin of error — having an accuracy of +/-0.1 mm. This allows manufacturers to create highly precise parts without the need for secondary services. In some cases, this high accuracy also means that no added tolerances are required.

Versatility

Some laser cutting machines are equipped with multi-axis layers. This mechanism allows them to cut a wide range of custom designs and shapes. And, they can cut materials of all different types and thicknesses — including other metals and alloys. These machines are capable of cutting even the most complex structures with ease.

Laser cutters can create complex shapes in a variety of materials — even capable of processing several different materials at once. These capabilities mean that the types of designs that laser cutting can fulfill are almost limitless.

Consistency

As laser cutters are highly precise and capable of working with a variety of materials, they can create parts and assemblies that are accurate and repeatable. You can ensure that the cuts will be exactly the same from the first part out of the machine to the thousandth part. This helps manufacturers create multiple copies of the same product, of the same quality, and in a consistent production flow.

Speed

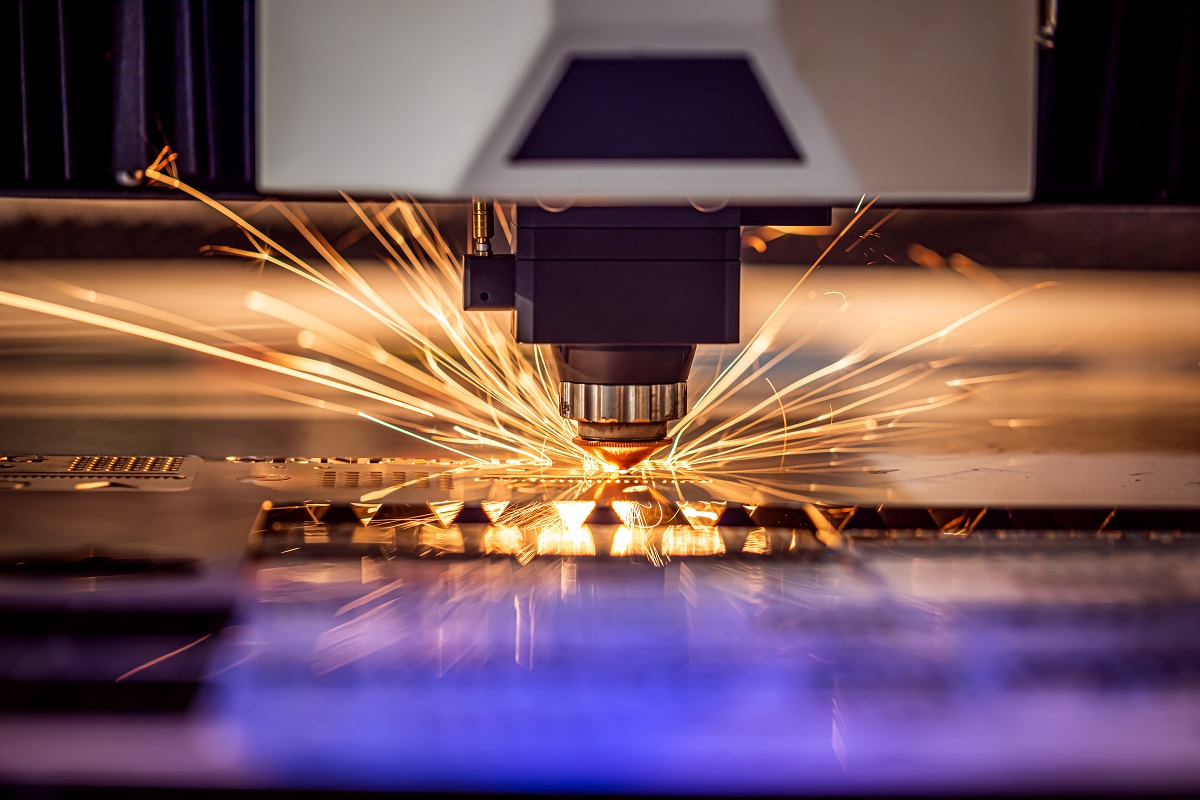

Laser cutting — aside from being precise and reliable — can be done a lot quicker than other cutting methods (especially traditional and mechanical options). This advantage is particularly useful in the case of more complex cuts.

When making complex or large metal assemblies, cutting using other methods like plasma or flame cutting can take a considerable amount of time. Laser cutting can break them in speed alone even with materials as thick as 10mm.

Automation

Using laser cutting also requires little manpower or human intervention to work properly. Thanks to technological advances, laser cutting machines are now highly automated. Nowadays, most machines are compatible with CNC CAD/CAM programs, feeding machines, and follow-up conveyors — which enhance their speed, precision, and consistency. While they still need experienced operators to ensure safety, proper cutting, and quality, there is now little need for manual labor throughout the entire process. Thus, laser cutting also has lower costs compared to other methods.

Reduced Finishing Requirements

Because laser cutters are highly precise machines, they tend to leave behind fewer surface imperfections (such as burrs). Edges made by laser cutters are smooth, and any burrs they leave behind are small and easy to remove.

Another advantage also comes from their precision. To achieve accurate cuts, laser cutter beams must be tightly focused. This means there is a smaller heat-affected zone (HAZ), which reduces the risk of internal flaws due to heat exposure — creating predictable, sturdy, and reliable metal parts.

Contactless Cutting

When using a laser cutting machine, only the focused beam comes into contact with the workpiece. Therefore — unlike with mechanical machines — there is less friction and force that could wear down the laser cutting tools. And, given that it is a noncontact process, there is less workpiece distortion, warping, tearing, and other problems common with mechanical methods.

Energy Usage

The efficiency and speed of laser cutting also lead to it using less energy overall when compared to other cutting methods. Typically, laser cutting machines will use around 10kW of power in one cutting session. Compared to the 50kW of power average of other cutting machines, laser cutting is more energy efficient by a landslide. Using a laser cutting machine is a great way to reduce your manufacturing project’s energy consumption and make your process more cost-efficient.

Key Takeaway

In a nutshell, there are multiple benefits to laser cutting. These benefits make it one of the most important and cost-efficient methods in the metal manufacturing process. Using laser cutting, many people have been able to get their products to the market in record time and with reduced costs overall.

Interested in using laser cutting for your product or next metal project? Consult with Metal Exponents today. With our years of experience, top-of-the-line equipment, and extensive product portfolio, we have the right set of skills across the board to help you create quality metal products for a variety of applications.