6 Important Shearing Machine Safety Precautions

What are some important shearing machine safety precautions?

- Check all covers and safety enhancements

- Wear proper clothing and PPE

- Keep away from cutting parts

- Keep the machine in shape

- Turn the lights up

- Turn it off properly after using

Working with and fabricating metal sheets is a job that requires the assistance of a shearing machine. The machine is a piece of powerful equipment that uses several blades to apply shearing force to the metal sheets fed to the machine. This will produce, cut, and create more sheets of various sizes and thicknesses. As with any, the machine has its fair share of dangers, so it’s important to know about the proper shearing machine safety precautions.

Shearing machines work with sharp cutting parts, and you can bet that machines that can cut metal can easily cut through skin and bone. That’s why not following all these safety precautions could lead to permanently disabled workers and plenty of time lost. To avoid such safety incidents, make sure to follow the safety precautions that we list below. Keep reading to learn more!

Check all covers and safety enhancements

The manufacturers of these types of machines are aware of the possible hazards they could bring to the workplace. You’ll find that there are built-in safety enhancements and covers on the machine to protect anyone operating them.

A good example is the finger protector which stops any operator to reach into the area where the blades are. Before using the machine, make it a habit to double-check all the covers, shields, and other safety enhancements on the machine. Their presence alone could prevent any unnecessary injuries.

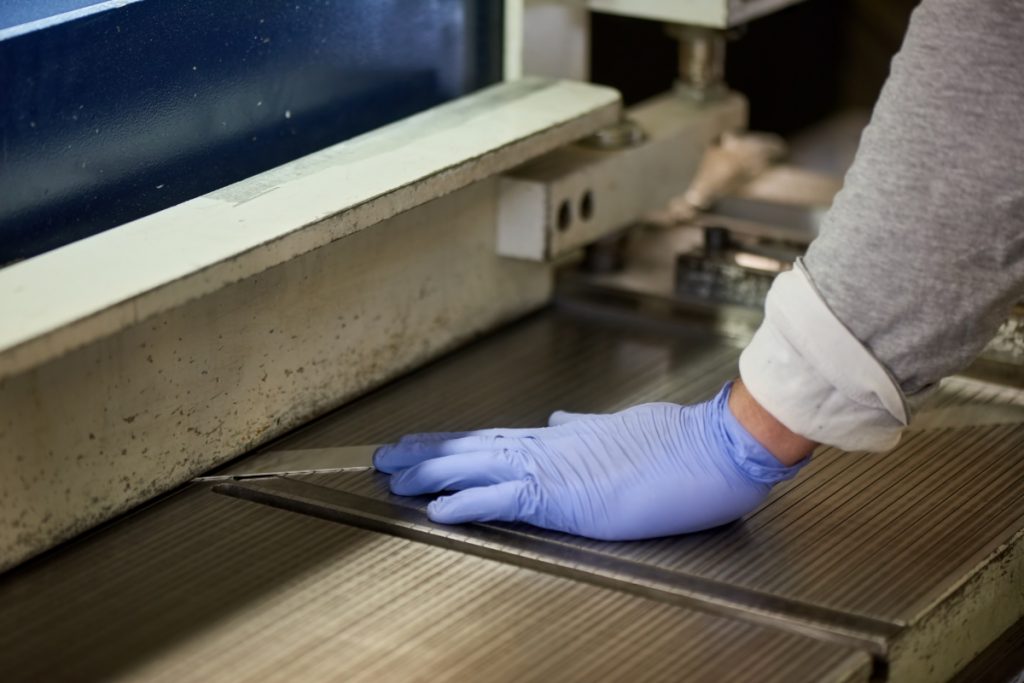

Wear proper clothing and PPE

When working with a shear machine, it’s important to avoid wearing any loose clothing that might get caught on the blades or any part of the machine. Any excessive jewelry, accessories, or even loose clothes are potential injury hazards. For the same reason, people with long hair should always keep it tied up.

In addition, personal protective equipment (PPE) should also be worn at all times in any metal fabrication workshop. This is one of the most common safety violations you’ll find in workshops, so try to be more strict in implementing it.

Keep away from the cutting parts

Regardless of the presence of protective shields and PPE, operators should refrain from being in the vicinity of the cutting parts of the machine. To make sure that no injuries happen, all precautions must be taken, both on the side of the equipment and the behavior of the workers.

This also comes with the familiarization of the employees with the equipment. Even if you know how the machine works, we never know when and where accidents may happen. Instead of risking losing a finger for nothing, just keep them away from the cutting parts.

Keep the machine in shape

The most basic tip in keeping safe when using machinery is by keeping it in good shape. Every single component of the machine works together to function properly. If even some of those parts are not fitted properly, broken, cracked, rusted, or not in a good condition, it makes the whole machine prone to catastrophic failure. And of course, that could lead to safety incidents with its sharp parts.

To prevent anything like this from happening, regular checks should be done on the machine. Replace any malfunctioning parts, oil parts that need to be lubricated, and double-check all warning lights, stop buttons, and mirrors if they are still working.

Turn the lights up

Some workshops don’t invest enough in good lighting. This could spell disaster when working with potentially dangerous machinery. Operators need to see what they are doing to avoid any accidents. Poor lighting is known to increase the number of on-the-job accidents and injuries, so make sure your shop is well-lit enough. Try switching to energy-efficient lighting options like LED lighting if you’re short on resources.

Turn it off properly after using

Shearing machines have proper lockout or tag-out procedures. Follow these procedures to avoid any malfunction. If you have to turn it off because of a malfunction or accident, use the emergency stop button.

In other situations, make sure the machine is all powered down before trying to fix the malfunction. Disconnect it from the power source if possible. Try to engage the parking brakes as well. This is all useful not only when you’re done using the machine for the day, but also when you need to clean trash buildup or make repairs.

Key Takeaway

The metal fabrication industry is populated with many heavy types of machinery as working with metal is not an easy thing to do. Learning these important shearing machine safety precautions is the best way to keep safe while using a shearing machine, but make sure you also know the general safety guidelines and safety measures for each piece of equipment you use.

Just as you should keep your machine in good shape, you should also get the best quality of metal products for your project. We at Metal Exponents pride ourselves in being the leading supplier of the finest steel from our partnerships all over Asia. Take a look at our products here, or contact us for any inquiries!