Guide to Sheet Metal Fabrication in the Philippines

Overview

- Sheet metal fabrication is the process that creates metal components from raw materials to suit exact specifications.

- Various techniques are used to create steel parts for different applications.

- This article delves into the fundamentals of sheet metal fabrication and Metal Exponents Inc.’s position as a premier steel supplier in the Philippines.

Sheet metal fabrication in the Philippines is a fundamental process that drives innovation and shapes industries worldwide. Its blend of engineering expertise and creative problem-solving makes it an invaluable asset for manufacturers striving for precision and efficiency in bringing their designs to life.

The demand for sheet metal fabrication services is soaring, with the global market valued at US $15.3 Billion last year. Projections indicate robust growth, expected to reach $19.6 Billion by 2030.

They play a pivotal role across diverse sectors nationwide, including construction, automotive, and machinery. Their versatility offers tailored solutions to meet specific business needs.

What is Sheet Metal Fabrication?

Sheet metal fabrication is the process of converting flat metal sheets into various metal products and structures. This versatile technique creates an extensive array of components using different types of sheet metals, including aluminum, steel, stainless steel, copper, and brass.

Various techniques are often combined to create one specific part. These techniques synergize with one another, each contributing crucially to the successful execution of a project.

Why is Metal Exponents Inc. Your Go-To Source for Sheet Metal Parts in the Philippines?

As one of the leading steel suppliers in the Philippines, Metal Exponents Inc. provides exceptionally competitive pricing on a wide variety of sheet metal parts and other steel products.

We offer a diverse range of options to meet your specific requirements, from sheet piles to strands, tubings, coils, and beyond. Our transparent pricing ensures you receive excellent value for your investment.

With our industry expertise and unwavering focus on safety, count on us for premium, tailor-made sheet metal fabrication.

What Techniques are Used for Sheet Metal Fabrication?

Sheet metal fabrication utilizes sophisticated techniques to demand precision and expertise to guarantee high-quality results.

Cutting

Cutting is an essential process in sheet metal fabrication. It allows for the precise shaping of metal sheets. Various cutting methods are employed, including shearing, laser cutting, waterjet cutting, and plasma cutting. Each method offers unique advantages and is chosen based on factors such as material thickness, complexity of the design, and required precision.

Bending

This technique uses metal brakes or form benders to create diverse shapes and angles, from simple to intricate designs. It requires skilled operators to manage challenges like spring back, where the metal reverts to its original flat state after bending.

Overbending is often employed to counteract this effect and achieve the desired final angle.

Forming

The forming process includes shaping flat sheets into three-dimensional objects or parts using various techniques such as stampings, deep drawing, and spinning.

Stampings and deep drawing involve pressing dies into the metal to create complex shapes or patterns while spinning shapes the metal around a mandrel to produce cylindrical, conical, or box-like shapes with depth.

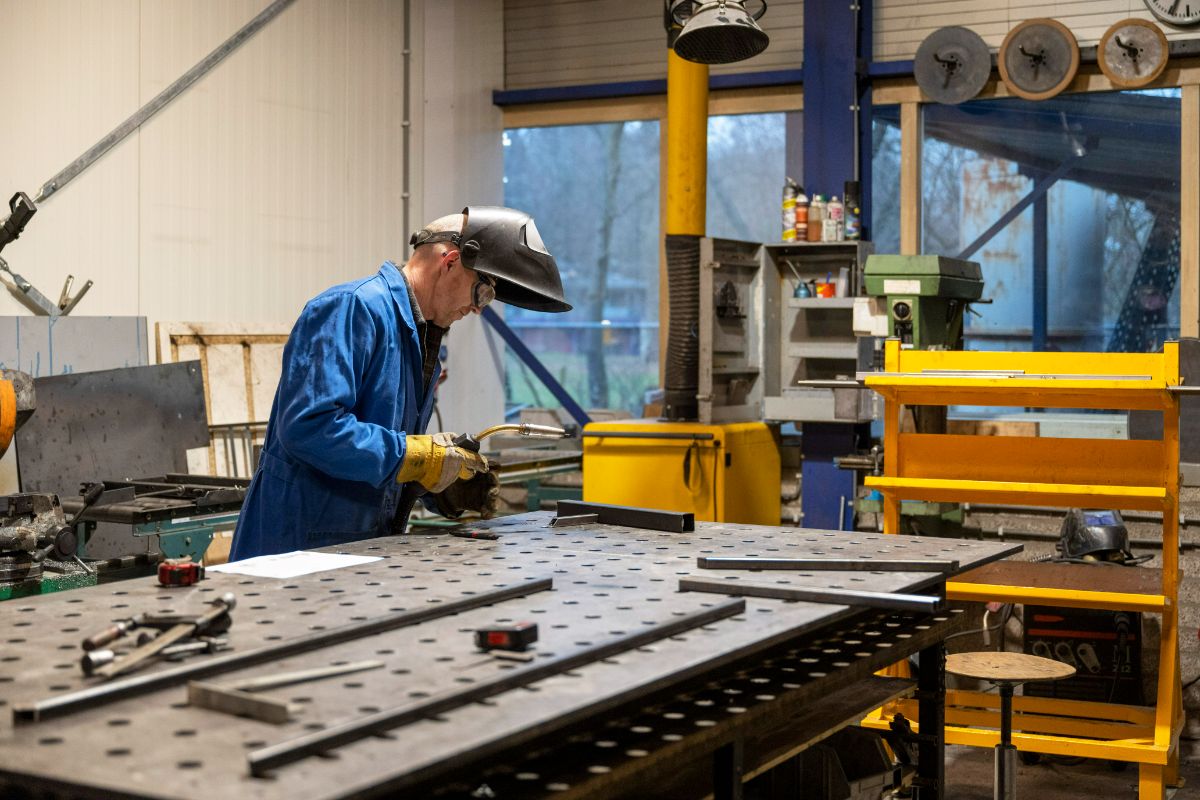

Welding

This process involves melting the edges of the metal pieces and adding a filler material to create a durable fusion, essential for assembling products with multiple separate components.

This technique fuses metal pieces to create a single part. Various welding techniques, including stick welding, MIG, and TIG welding, achieve strong bonds between metal components.

Assembly

Aside from welding, sheet metal assembly combines various components using methods like riveting, screwing, adhesive bonding, and clinching.

The choice of assembly method depends on design requirements and the type of metal used. Selecting the right technique ensures the functionality and integrity of the final product.

Various Applications of Sheet Metal Fabrication

Steel fabrication remains a vital process for ensuring the integrity, safety, and longevity of diverse projects and products across various sectors.

Automotive

The automotive sector is a significant user of sheet metal, using it extensively in the production of various components like doors, hoods, and roofs. This preference stems from the remarkable versatility and durability of sheet metal, facilitating a broad spectrum of fabrication techniques such as bending, shaping, welding, and forming.

Construction

Sheet metal serves many purposes in construction, ranging from providing protective coverings for buildings to forming roofing systems and exterior cladding. Its durability and ability to withstand various weather conditions make it an ideal choice for ensuring both structural integrity and aesthetic appeal in construction projects.

Industrial Machinery

Sheet metal is essential for creating precise and robust components needed in various industrial machines and tools. From intricate parts for robotics to components in manufacturing equipment and automated machinery, sheet metal’s ability to be molded and shaped precisely according to specifications makes it invaluable in the field of automation.

Key Takeaway

Sheet metal fabrication in the Philippines offers an efficient solution for producing precision-cut components in large volumes. Leveraging the inherent properties of this versatile material alongside advanced machine tools enables manufacturers to enhance product quality significantly while reducing operating expenses.

Metal Exponents Inc. takes pride in offering durable products, dependable delivery, and competitive rates, positioning us as leaders in imported steel. For top-quality steel products for your upcoming project, contact us today.