Tubular Steel Price Comparison: Local vs Imported Steel in the Philippines

Overview

- This article compares the pricing of local versus imported tubular steel in the Philippines, highlighting key factors that influence costs such as raw material quality, manufacturing processes, and logistics.

- While local steel is more affordable due to lower transportation fees, imported steel offers superior quality and durability, making it a valuable long-term investment for demanding projects.

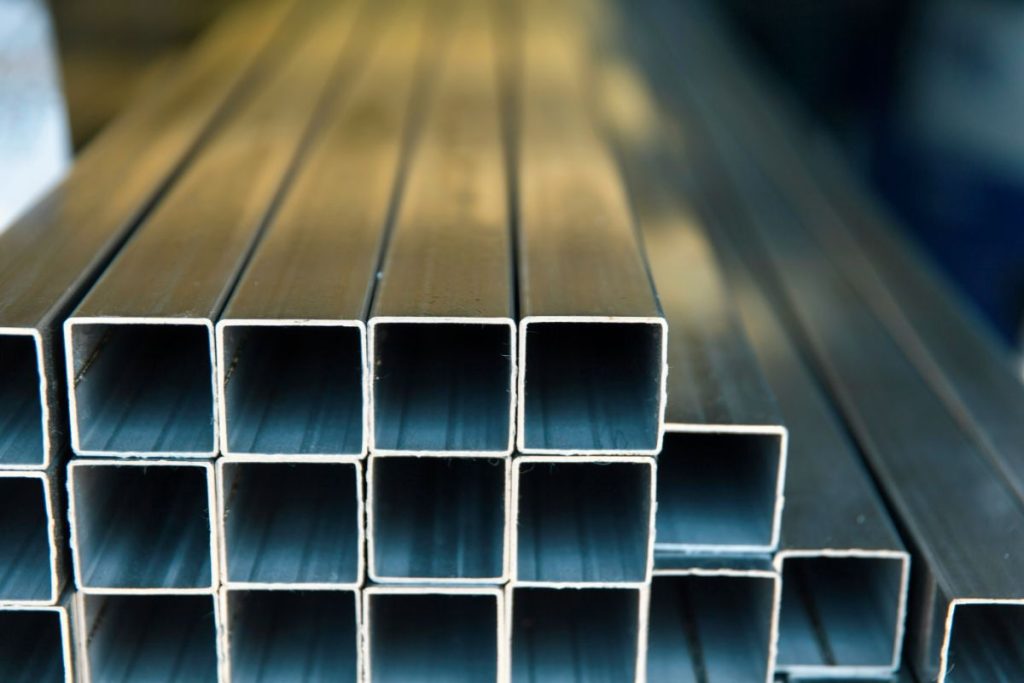

When it comes to construction, one of the most crucial decisions you’ll make is choosing the right materials. Tubular steel, renowned for its strength, durability, and versatility, is a popular choice for a wide range of building projects. However, with a growing market for local and imported options in the Philippines, navigating the price difference between these two can be a challenge.

Understanding the factors that influence its price—from manufacturing processes to logistics and material quality—is key to making an informed decision. In this article, we’ll explore tubular steel price comparison, so you can choose the best option that fits your budget and construction needs.

Price Comparison on Local vs. Imported Tubular Steel

The price comparison between local and imported tubular steel involves examining key factors such as material quality, shipping costs, and supply chain dynamics. This makes it important to weigh both options based on your specific needs.

Initial Cost Differences

Local steel generally has a pricing advantage due to lower shipping fees and the absence of import duties and customs taxes. This makes it an attractive choice if your projects have a tight budget or require a bulk purchase.

While often more expensive upfront because of additional costs like shipping and import taxes, imported tubular steel can offer superior quality and advanced manufacturing qualities that justify its higher price.

International manufacturers often benefit from economies of scale, enabling them to invest in state-of-the-art technology, stricter quality control measures, and innovation in production, which result in more consistent and higher-quality steel products.

Long-term Value

Imported tubular steel offers enhanced durability due to advanced manufacturing processes, which can reduce maintenance and replacement costs over time. Its corrosion resistance and long-lasting performance also make it a valuable investment, especially in demanding environments, ultimately contributing to long-term savings and reliability.

On the other hand, locally sourced steel manufactured with the Philippine environment in mind can also ensure better performance and longevity in local conditions. Maintenance and repair costs may also be lower, as local products are typically more accessible, and suppliers can quickly address any issues.

Quality of Materials

Imported tubular steel often comes with advanced manufacturing techniques and higher-grade raw materials, which contribute to its durability and strength, reflecting its higher cost.

Meanwhile, local tubular steel, while more affordable, still meets industry standards and offers reliable performance, especially for projects within the local environment.

Both options provide excellent reliability and durability, and the price difference reflects factors like sourcing, manufacturing, and logistics.

Factors Affecting Tubular Steel Prices

The price of tubular steel can be influenced by several factors, each playing a significant role in determining the final cost of the material. Here are the factors that shape the overall price structure of both.

Raw Material Costs

The production of tubular steel relies on raw materials like iron ore, scrap metal, and various alloys. The cost of these materials fluctuates based on global supply and demand, meaning any increase in raw material prices directly affects the overall cost of steel.

Higher-quality raw materials often result in stronger, more durable steel, but they can also contribute to a higher price. Therefore, the cost of raw materials determines the price of tubular steel, making it a key factor to consider when assessing overall costs.

Manufacturing Processes

The tubular steel manufacturing process includes the methods used to shape, heat, and treat the material, which has a significant effect on its price. Steel that requires advanced production methods, such as high-temperature rolling, precise welding, or special treatments for added strength or corrosion resistance, will cost more.

These processes not only require specialized equipment but also skilled labor, both of which contribute to the final price of the steel. More intricate manufacturing processes result in higher-quality steel but also drive up production costs.

Logistics and Transportation

Transportation fees, fuel costs, and the distance between manufacturing sites and delivery locations all contribute to the price of tubular steel. Imported steel incurs additional expenses for shipping, customs clearance, and handling, which can significantly increase the final cost.

On the other hand, local steel tends to have lower transportation costs, making it more affordable for regional buyers, especially for large construction projects.

However, Metal Exponents Inc. offers imported tubular steel, ensuring businesses can still take advantage of the superior quality and advanced manufacturing qualities of imported steel while benefiting from competitive pricing.

Key Takeaway

The tubular steel price comparison between local and imported steel ultimately depends on the specific needs of your project. It’s essential to evaluate factors, such as the project’s scale, required material properties, and long-term durability needs when making your decision.

If you’re looking for a reliable steel supplier in the Philippines, Metal Exponents Inc. is here to provide high-quality tubular steel for your construction needs. With years of experience and a commitment to delivering top-grade materials, we ensure your project is built on a foundation of durability and strength. Contact us today to discuss how we can support your next project with dependable steel solutions.