Types of Steel Angles

What are the common types of steel angles?

- Equal angle

- Unequal angle

- Rolled steel angle

- Cold-Formed steel angle

- Galvanized steel angle

- Stainless steel angle

Overview

- Steel angles serve as fundamental structural elements extensively employed in construction and engineering endeavors, which are valued for their robustness and adaptability.

- Grasping the attributes and uses of diverse steel angle varieties is important for proficiently integrating these elements into their architectural and constructional undertakings for engineers, architects, and construction practitioners.

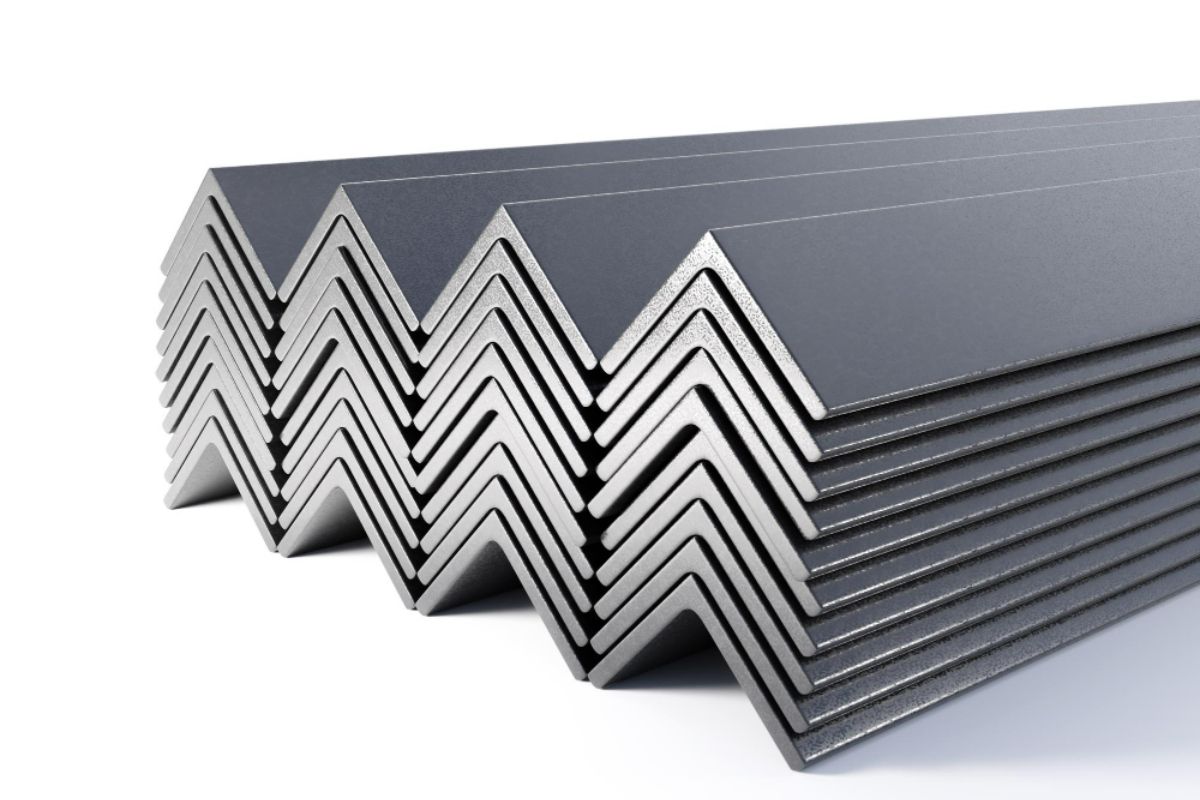

Steel angles are structural components widely used in construction and engineering projects for their versatility and strength. They provide support, stability, and reinforcement in various applications, ranging from building frameworks to machinery fabrication.

Understanding the characteristics and applications of different types of steel angles is important for engineers, architects, and construction professionals to effectively these in their designs and constructions.

Equal Angle

Equal angles, commonly referred to as L-shaped angles, are structural components characterized by having equal-length legs meeting at a 90-degree angle. Their symmetrical shape ensures uniformity and balance, making them highly versatile for a wide range of applications.

These angles are utilized in bracing systems to resist lateral forces and enhance structural integrity. They are employed for constructing support beams, guardrails, and signposts, contributing to the integrity of transportation networks and utility systems in infrastructure projects.

Unequal Angle

Unequal angles are distinguished by having one leg longer than the other, which offers a versatile solution for applications—where unequal distribution of forces is necessary or aesthetic considerations dictate asymmetrical profiles. Their design flexibility makes them indispensable in various industries, including construction and manufacturing.

They are applied in construction for trusses, and floor framing, as well as in industrial machinery for structural components—where specific load-bearing requirements or aesthetic considerations dictate unequal distribution of forces.

Furthermore, their unequal geometry allows engineers and architects to tailor the angles to the unique demands of each application.

Rolled Steel Angle

Rolled steel angles are produced through a meticulous manufacturing process, wherein heated steel billets are fed through a succession of rollers to attain the desired angle profile. This method guarantees precise dimensions and uniform mechanical properties, rendering rolled steel angles exceptionally suitable for various structural and fabrication applications.

They are in demand for framing structures, fabricating machinery components, and building support beams and frameworks in both the construction and manufacturing sectors.

Their ability to withstand heavy loads and harsh environments makes them a preferred choice for engineers and architects seeking dependable solutions for their projects.

Cold-Formed Steel Angle

Cold-formed steel angles are crafted through a precise manufacturing process. This involves bending or folding sheet metal or strip steel at room temperature eschewing the need for heat. This offers several advantages, foremost among them being the ability to create angles with intricate geometries and tight tolerances. These steel angles are highly customizable to meet specific project requirements.

Common applications include partitions, shelving systems, and architectural details, where cold-formed steel angles contribute to both the structural integrity and aesthetic appeal of the final product. Their versatility, coupled with the ability to achieve complex shapes with consistent quality makes cold-formed steel angles a preferred choice in various industries ranging from construction to interior design.

Galvanized Steel Angle

Galvanized steel angles undergo a process called galvanization—coated with a protective layer of zinc. This coating serves as a barrier that significantly enhances the corrosion resistance of the steel. This makes them a preferred choice for various applications in construction, fencing, and outdoor structures.

These angles are particularly well-suited for outdoor and marine environments where exposure to moisture, saltwater, and harsh weather conditions is prevalent. They offer long-lasting durability and reliability even in challenging environmental conditions.

Stainless Steel Angle

Stainless steel angles represent a pinnacle of durability and aesthetic allure. This is due to the fact they are crafted from a corrosion-resistant alloy steel blend containing chromium and nickel. This unique composition imbues them with unparalleled corrosion resistance. This makes them particularly well-suited for architectural and decorative applications, for which longevity and visual appeal are important.

They can be utilized in architectural designs, decorative elements, and industrial applications like food processing facilities and chemical plants. These angles stand as a testament to both form and function—whether adding a touch of sophistication to architectural designs or providing robust structural support in corrosive settings.

Key Takeaway

The different types of steel angles offer a wide range of applications across multiple industries, from construction and manufacturing to infrastructure and architectural design. Each type serves a unique purpose tailored to specific project requirements.

Prioritizing quality, reliability, and excellent customer service remains important. This underscores the importance of considering Metal Exponents as your partner for steel angle needs. Renowned for delivering high-quality and competitively priced steel products in the Philippines, we ensure industry-grade steel angles for your projects. Reach out to us today to elevate your steel solutions.