5 Uses Of Metal Casting

What are the uses of metal casting?

- Automotive

- Medical

- Electronics

- Aerospace

- Plant Machinery

Metal casting is a thousand-year-old metalworking technique that dates back to 3200 BCE and was first used in manufacturing and fine art. Over the years, new metal casting processes were developed and became widely used for creating various objects, like jewelry and weapons.

Today, metal casting is one of the most widely used manufacturing methods for complex forms, which would otherwise be time- and material-consuming to make with other methods. In this post, we share a few common uses of metal casting, and how it is used to make items we see every day.

What Is Metal Casting?

Metal casting involves the use of molds and various metals. In it, the metal is molten and then poured into a mold to create the desired shape. The solidified shape is known as a casting, which is then ejected or broken away from the mold cavity to complete the process.

What Metals Can Be Used For Casting?

Almost any metal or metal alloy can be used for metal casting. But, the most common materials for this method are ferrous — this includes ductile iron, malleable iron, gray iron, and steel.

Aside from those, aluminum is also a popular casting material. Alloys containing iron and steel are typically used for high-performance applications for their improved resistance to temperature, wear, and corrosion.

Automotive

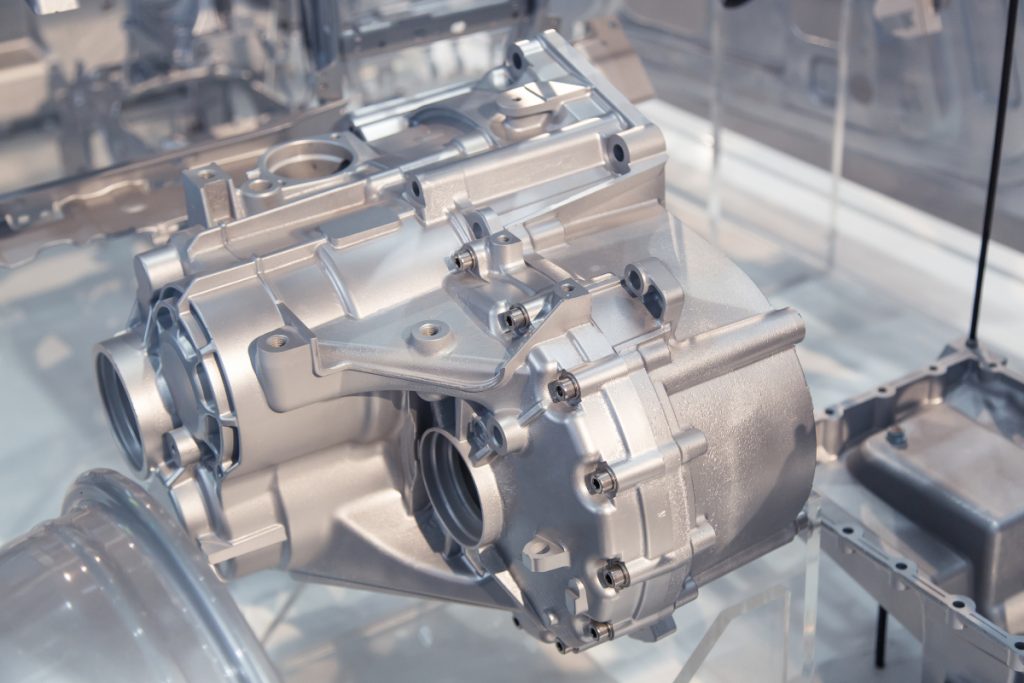

The automobile industry uses metal casting to make various components using ferrous, non-ferrous metals and their alloys. This industry uses different casting methods to make these components as it is an effective way to create parts that are lightweight, easy to install, and cheap.

Die casting is the most popularly used casting process in this industry, while zinc and aluminum are the most commonly used metals to produce automobile casting equipment. These metals are ideal as they are just ⅓ of the weight of steel parts while maintaining good durability. This method, on the other hand, is ideal as it can be used to create thousands upon thousands of parts per day.

Metal casting in the automotive industry is typically used to make items like valve covers, transmission housings, engine blocks, carburetors, fan clutch, and alternator housing.

Medical

The medical industry makes use of metal casting because it is a quick process. In this application, metals like stainless steel and aluminum are most commonly used. These metals offer superior strength, cleanability, and lightness — qualities that many medical and healthcare products need to have.

The medical industry typically uses rapid metal casting, as products need to be fabricated quickly and in small quantities, while also meeting tight tolerances and strict requirements.

Common metal cast medical parts include pacemakers, hospital bed parts, monitors, oxygen pumps, stethoscopes, dialysis machine parts, pacemakers, and other similar products.

Electronics

Mass production for electronic parts — both industrial and commercial — is common, which is why metal casting is a valuable method for this industry. Metal casting allows the electronics industry to quickly prototype electronic parts, create short-run orders for specialist equipment, and create high-quality housings and assemblies for a variety of products.

Telecommunications equipment in particular use metal casting and zinc, magnesium, and aluminum metals often, due to their high conductivity, low weight, and durability.

Common metal cast electronic parts include items like headphone housings, camera chassis, smartwatch components, couplings, and other enclosures for commodity electronics. Specialty components, such as RF filters and antenna mounts can also be made by die casting.

Aerospace

Metal casting is also applied in the aerospace industry. From civilian aircraft to jet fighters, there are several applications for this method. In particular, magnesium, aluminum, and their alloys are the most widely used in the industry due to their favorable durability, weight, and resistance even under increasingly demanding conditions.

In the last decade, magnesium alloy castings have become the most popular choice in aerospace due to their superior corrosion performance. These alloys also offer low density and excellent temperature mechanical properties. It is used to create helicopter transmission casings, generator housings, canopies, compressor casings, and even airframe-mounted auxiliary drive systems (AMADS) as in fighter jets.

For aluminum alloys, they are used mostly in nonstructural airplane hardware. Parts like pulleys, brackets, door handles, waveguides, hydraulic control systems, and the like are often made from metal casted aluminum.

Plant Machinery

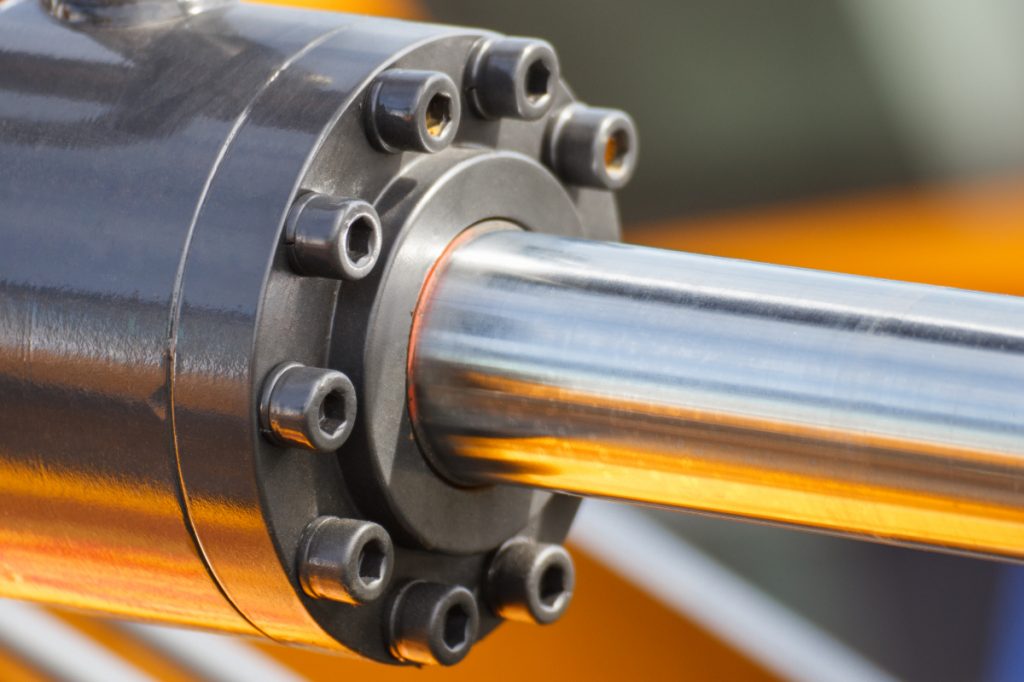

For plant machinery — especially those that transport sensitive chemicals and materials — corrosion resistance is of utmost importance. Aside from that, it is desirable to have machinery that is both light and strong. For that reason, metal casting is the preferred method for making a variety of industrial equipment. In regards to the material, titanium is the most common metal used in metal casting for plant machinery.

Some common examples of industrial plant products fabricated from metal casting and titanium are manufacturing equipment, such as vats, filters, and pressure vessels. Titanium can also be cast to make tubing for heating and laboratory applications, as well as transporting materials such as petroleum, sugar, acid, and inorganic salts.

Key Takeaway

The rich and varied uses of metal casting have made it an invaluable manufacturing method for many industries. Metal casting can be used to make even the most complex, specialized products — all while remaining a time- and cost-effective metalworking method.