4 Ways for Blueing Steel

What are the different ways of steel blueing?

- Hot Blueing

- Cold blueing

- Rust Blueing

- Nitre Blueing

Overview

- This article explores various blueing methods used to protect steel from rust and corrosion, especially in harsh environments like the Philippines.

- It covers techniques such as hot blueing, cold blueing, rust blueing, and nitre blueing, each suited for different applications.

- Whether for industrial use or preserving high-end items, understanding these methods helps ensure optimal performance and longevity of steel products.

Steel is prone to rust and corrosion, especially when exposed to harsh elements like moisture, humidity, or salty air, which are particularly common in the Philippines. To combat this, blueing is often used to create a protective oxide layer on the steel’s surface. It acts as a barrier against environmental factors that cause rust and corrosion. This reduces oxidation and protects the material’s structural integrity.

In this article, let’s explore ways for blueing steel, each suited to different applications. Whether you’re a manufacturer or simply looking to maintain steel items, understanding these techniques will help you select the best process for your needs.

Hot Blueing

Hot blueing is one of the most commonly used blueing methods, especially in industry settings, due to its effectiveness in creating a durable, corrosion-resistant finish. It involves submerging steel in a heated chemical bath containing a blend of salts like potassium nitrate, sodium hydroxide, and sodium nitrite.

The steel is heated to temperatures between 275-311°F (137-154°C), initiating a chemical reaction where the salts bond with the steel’s surface to form a protective oxide layer.

This process is also widely applied in automotive parts, machinery components, and construction equipment.

Cold Blueing

Cold blueing is a more accessible and cost-effective method of blueing steel, ideal for smaller projects or touch-ups, Unlike hot blueing, this one doesn’t require a heated bath. Instead, it involves directly applying a chemical solution containing selenic acid to the steel surface, where it reacts with the metal to form a blue-black oxide layer.

Essential tools for cold blueing include applicator brushes, degreasers, lint-free cloths, fine-grit sandpaper, nitrile gloves, and safety goggles. Each of these tools aids in achieving a smooth, effective finish on the steel.

Rust Blueing

Rust blueing, an older yet highly effective technique, remains popular for high-end or antique steel items due to its durability and aesthetic appeal. In this process, a chemical solution is applied to the steel to induce controlled rusting, which is then removed through a boiling process. This converts the rust into a black oxide layer, creating a finish that is highly durable and corrosion-resistant.

Though labor-intensive and time-consuming, this blueing technique is preferred by gunsmiths, antique restorers, and custom metalwork artisans. It is ideal for applications where a meticulous, high-quality finish is essential, such as crafting bespoke steel items like custom knives, luxury firearms, high-end tool parts, handcrafted locks, and designer metal furniture.

Nitre Blueing

Also referred to as fire bluing, nitre blueing is a heat treatment process that involves heating steel in a bath of potassium nitrate and other salts. As the steel reaches high temperatures, the nitrates react with the surface, forming an oxide layer that results in a striking blue or purple finish. The exact color achieved depends on the temperature, with deeper blues and purples emerging at higher temperatures.

This blueing technique provides a durable protective layer and delivers a highly decorative and vibrant finish. Unlike other methods that produce more uniform colors, nitre blueing creates a unique, multicolored effect, ranging from deep blue to rich purple tones.

Ideal for premium steel items where both functionality and aesthetic appeal are essential, it enhances the beauty and longevity of products such as firearms, custom knives, and high-end metal tools.

Why You Should Get Your Steel Products at Metal Exponents Inc.?

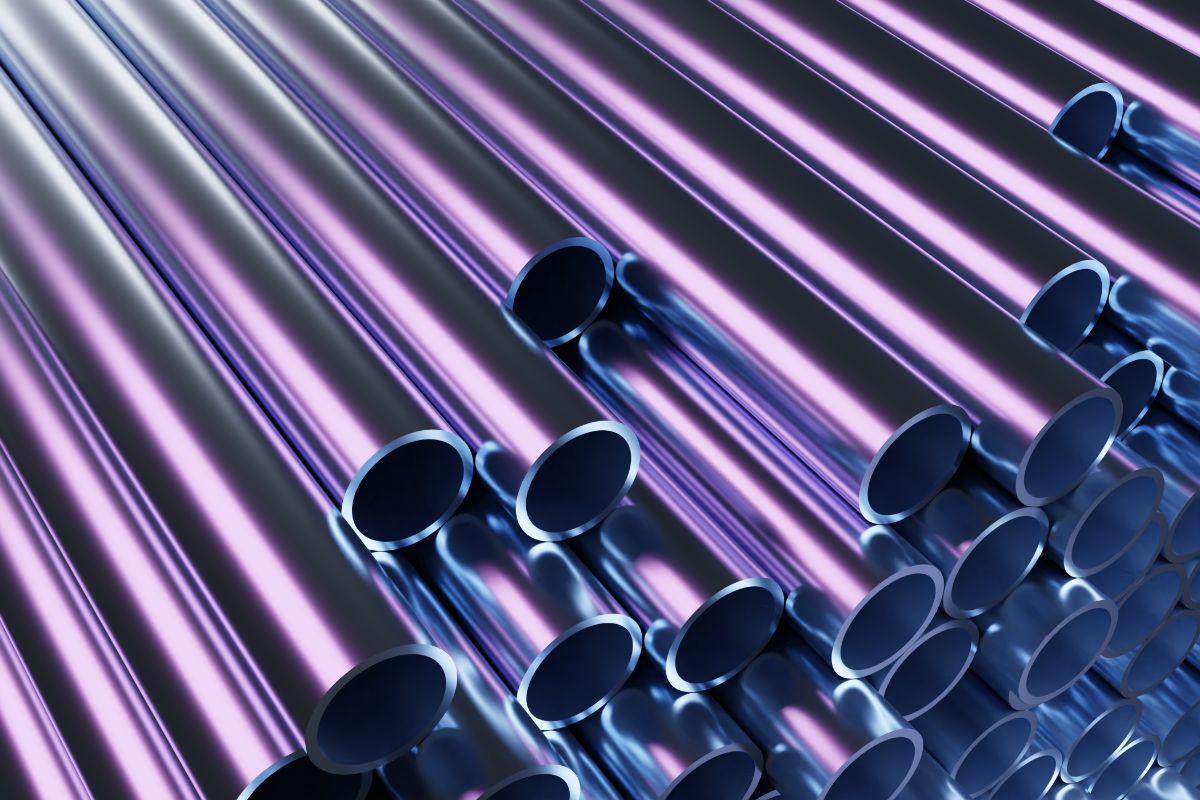

With over 40 years of industry experience, we specialize in providing high-quality imported steel products to the Philippines. Our extensive range, including pipes, sheet piles, tubing, coils, and more, is sourced from trusted suppliers to ensure superior strength and durability. Designed to withstand wear, corrosion, and deformation, our steel products offer long-lasting performance for various applications.

Key Takeaway

Each way of blueing steel has its applications, depending on your desired result, the scale of production, and the steel item being treated. Before deciding on a blueing method, assess the conditions your steel will be exposed to, as well as the level of protection and appearance you’re aiming for, to ensure you choose the most effective process.

Metal Exponents Inc. is a trusted supplier in the Philippines for those looking to source high-quality steel materials. With our commitment to delivering top-tier steel products, you can rest assured that your steel components will meet the highest quality and performance standards. Contact us today and ensure your projects stand the test of time with high-quality steel products.