What is the Best Steel Tubing for Automotive Frame Fabrication

Overview

- Selecting the best steel tubing for automotive frame fabrication is essential for achieving durability, resilience, and safety.

- This article explores key steel types like high-strength low-alloy (HSLA) steel, highlighting its advantages in strength, weight efficiency, and corrosion resistance.

- With additional insights into design flexibility and aesthetic appeal, this guide provides manufacturers with practical considerations for superior automotive frames.

Choosing the right steel tubing for automotive frame fabrication is crucial to achieving a balance between strength, durability, and flexibility. The frame is the vehicle’s backbone, supporting its weight the stress of the road, and the demands of high performance. A well-chosen steel tubing material can drastically improve safety, handling, and the vehicle’s overall lifespan.

As the industry evolves, steel suppliers like Metal Exponents have become essential partners for manufacturers in search of high-quality steel tubing solutions. We provide a diverse range of steel tubing options tailored to meet the unique demands of automotive applications.

In this article, we’ll explore the types of steel tubing most suited for automotive frames, weighing their unique properties to help you determine the best choice for your fabrication needs. With the right one, you’ll be equipped to build a frame that meets the highest standards of resilience and performance.

What is the Best Steel Tubing for Automotive Frame Fabrication?

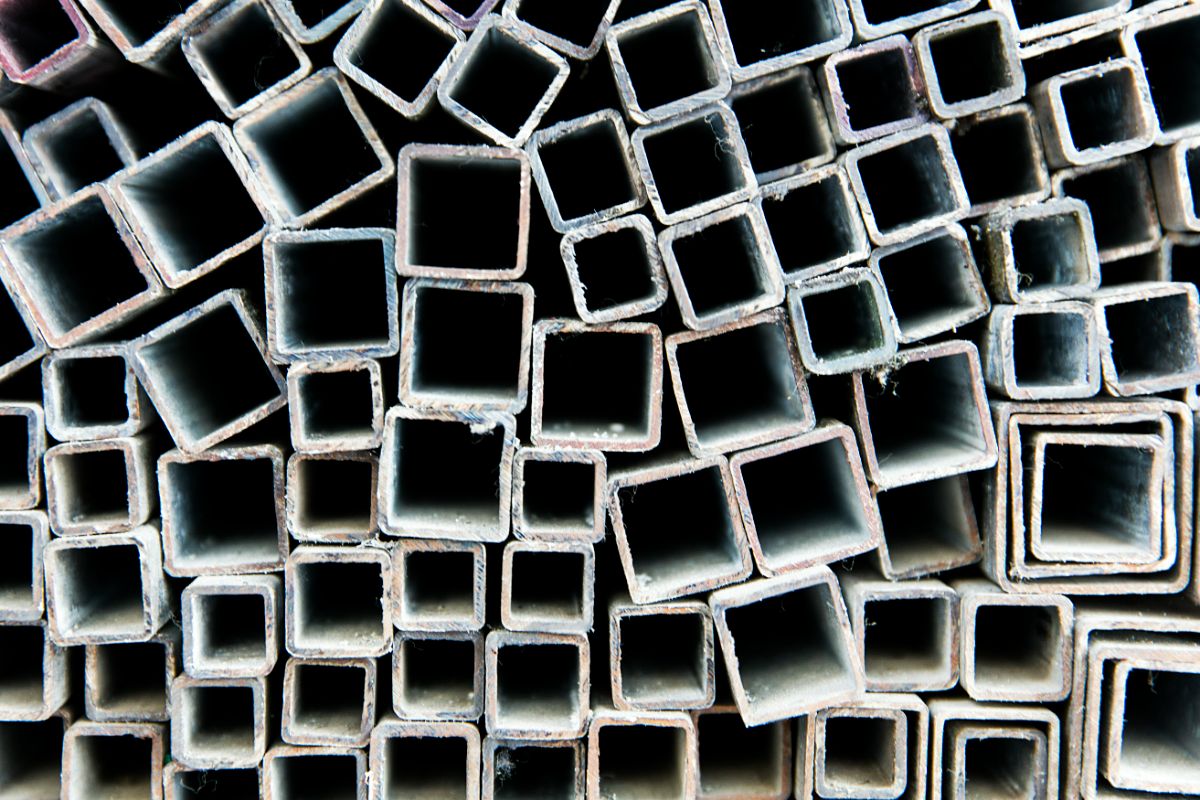

The ideal steel tubing for automotive frame fabrication includes high-strength low-alloy (HSLA) steel, valued for its optimal balance of strength, weight, and weldability. HSLA steel is engineered to deliver enhanced mechanical properties and corrosion resistance while being lighter than traditional mild steel.

This type of steel enables manufacturers to produce frames capable of withstanding high stress and impact loads, ensuring both safety and durability without sacrificing fuel efficiency.

Benefits of Using Steel Tubing for Automotive Frame Fabrication

As automotive manufacturers strive to balance safety, efficiency, and style, understanding the benefits of using steel tubing becomes essential for those looking to stay competitive in the market.

Corrosion Resistance

Steel tubing can be enhanced with coatings and treatments that boost its resistance to rust and deterioration. One common example is galvanized steel tubing, which is coated with zinc to create a protective barrier against moisture, salt, and other corrosive elements that cause rust. This treatment is especially beneficial for vehicles in coastal areas or regions with heavy road salt usage during winter months.

Stainless steel is another corrosion-resistant option, often used in high-end automotive applications for its natural resistance to oxidation. Stainless steel frames withstand harsh environmental conditions and provide a durable structure, ensuring critical components remain intact during impacts, thus enhancing vehicle safety.

Strength and Durability

With its high strength-to-weight ratio, steel tubing provides a robust framework that safeguards both the vehicle and its occupants. Unlike other materials, steel resists deformation and breakage under heavy loads, a critical feature in collision scenarios.

Through advanced manufacturing techniques like heat treatment and alloying, it can be further optimized for exceptional strength and resilience, making it ideal for constructing frames designed to last the vehicle’s lifetime with minimal wear.

This durability contributes significantly to the vehicle’s longevity and safety, particularly in demanding applications such as off-road vehicles and heavy-duty trucks.

Aesthetic Appeal

Steel tubing, with its versatility in shape and finish, empowers engineers and designers to create frames that are both durable and visually appealing. Its capacity for smooth lines and minimalistic structures allows for clean, streamlined aesthetics, meeting consumer expectations for both function and style. This flexibility enables various shapes and contours, giving vehicles a distinctive look that combines robust strength with unique design.

Its polished finish integrates seamlessly into a vehicle’s overall aesthetic. Unlike materials that require extensive processing for a refined appearance, steel tubing can be finished in a high gloss or matte style, aligning with diverse design themes. From luxury sedans to high-performance vehicles, the modern look is achievable elevating brand image and appealing to style-conscious customers.

Lightweight

In motorsports, where every ounce matters, utilizing lightweight steel tubing can lead to faster lap times and improved maneuverability. Similarly, electric vehicles benefit from reduced weight, which can extend battery life and driving range.

The ability to produce frames that are both lightweight and durable allows automotive manufacturers to meet the growing consumer demand for high-performing, energy-efficient vehicles, creating a competitive edge in the market.

This combination of performance and efficiency underscores the strategic importance of incorporating lightweight steel tubing in automotive frame fabrication.

Key Takeaway

Selecting the best steel tubing for automotive frame fabrication is essential for achieving optimal performance, safety, and durability in vehicle design. When you understand the various types available and their specific benefits, you can make informed decisions that will ultimately lead to high-quality vehicles that meet consumer demands and industry standards.

Metal Exponents Inc. is your trusted partner for high-quality steel tubing designed for various applications, including automotive frame fabrication. Our commitment to excellence, competitive pricing, and extensive inventory ensures that you find the right materials to meet your project needs. Contact us today to learn more about our products and how we can support your next project.